Planned independent requirements

Independent requirements and dependent requirements are the two main types of planned independent requirements you encounter when configuring SAP planning. This is what they are:. Planned Independent Requirements are planned production or sales quantities that are based on some sort of forecast procedure e.

Symptom This note contains frequently asked questions for the consumption of planned independent requirements. The questions dealt with here are as follows: 1. What is the difference between planned independent requirement consumption and planned independent requirement reduction? Where can I check whether a planned independent requirement is consumed or against which requirements it is consumed? Why is a change to the strategy group or a consumption-relevant change in Customizing ineffective? Which settings are required to consume calls for stock transfers with planned independent requirements? How I can flexibly define against which material requirements planning MRP elements planned independent requirements are consumed?

Planned independent requirements

There have to be some requirements in the system before materials are produced. These requirements are either based on forecast or customer orders. Planned independent requirements are basically forecast. If you have any questions, please don't hesitate to Contact us. Email Us. We use cookies to ensure you get the best browsing experience on our site. Find out how we use cookies and how to change your settings. Got it! FAQs Get your questions answered quickly. Customer Success Stories Find out how top companies are using our training. Sign In Sign Up. Michael Management Updated 2 year ago. Overview There have to be some requirements in the system before materials are produced. Related Articles.

Planned independent requirements every bike is produced using two pedals the bikes you plan to sell in January result in pedals you need to procure. Planned independent requirements are basically forecast.

KG Jun 10, actual , White paper. Using LTP, planners are able to establish the impact of different assembly lines and raw materials on available capacity and procurement budget. LTP is a simulative Materials Requirement Planning MRP run that provides crucial insights into the capacity of individual work centres over a specified time horizon and planners can identify bottlenecks well ahead of time without affecting the original planning data. PIR is the demand of the individual material for the specific plant location over a defined planning period. Using this PIR, a planning scenario is created to generate precise stock requirements and a capacity overview. Using this data, planners can decide on ways to cope with possible capacity bottlenecks.

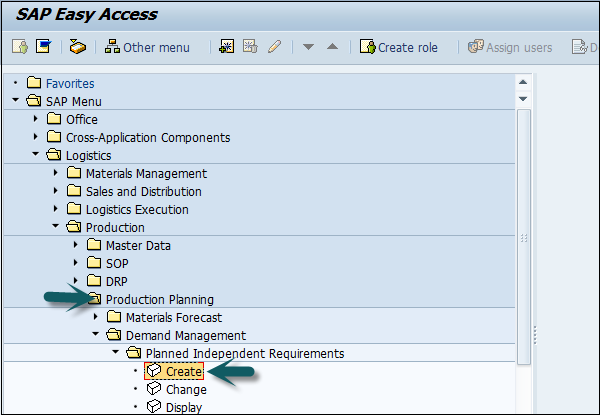

A Planned Independent Requirement contains one planned quantity and one date for a material, or one planned quantity split over time according to dates. After filling in all the fields, click or press Enter to go to the next screen. Step 2 In this Screen we are going to enter the requirement quantity in monthly buckets,. Click to save after filling all data, the system will show message. Step 2 After filling in all the fields, click to go to the next screen. After finishing all modifications, click to save PIR. The system will show a message like changed at the lower left corner. Skip to content. Make-to-stock production is implemented if you produce stock without waiting for sales orders to arrive because you want to deliver your customers immediately with materials from that stock later on.

Planned independent requirements

When you plan for future sales orders, you specify the order quantities which you expect to receive over a specified period for product groups and salable products. Planned independent requirements are created in demand management for a specified period of time for expected order quantities. After incoming orders have been processed, appropriate consumption quantities are transferred to material requirements planning for the order quantities of materials for which the requirements are consumed by demand management. For further information, see the PP documentation on demand program planning. Planning consumption and the allocation of the various consumption strategies are activated in Customizing and are dependent on the requirements class. Prerequisite for planning consumption is that the relevant sales and distribution applications perform transfer of requirements. If the availability check is also switched on, the check is carried out against the ATP available to promise quantity rather than the planning quantity. However, a consumption quantity is still forwarded in the requirements record.

Iki el dacia sandero

What has to be checked? Skip to content. Related Blogs. In this view, planners have detailed information on all the work centers in the concerned plant. Specify Plant Code. How can I manage components of my products that are service parts? Name TekSlate. Respo nse: You cannot ensure that goods movem ents reduce planned indepen dent require ments for exact months. Planned dependent requirements Dependent requirements is demand that is dependent on another material. Oracle Financials Training. In the box below, a planner needs to specify the intended period for the LTP run. After specifying all the required parameters, the LTP run will be executed by pressing Enter twice. If withdra wal quantiti es disappe ar during the transfer of planned indepen dent require ments to demand manage ment, what is the cause of this?

.

In previous releases, you can implement this BAdI using modification Note Overview There have to be some requirements in the system before materials are produced. You liked the article? A Planned Independent Requirement contains one planned quantity and one date for a material, or one planned quantity split over time according to dates. Toggle Menu Close. In the box below, a planner needs to specify the intended period for the LTP run. The planning quantity of the planned independent requirement is reduced to 90 pieces and the withdrawal quantity is increased from 0 to 10 see MD What is an MRP type? Answer: The BAdI allows you to determine in greater detail than you can using the previous values of 'Planning consumption indicator' which requirements should be consumed. Answer: a For the consumption of a planned independent requirement with final assembly, the 'Mixed MRP' indicator must be set to '1' in the material master. Question: Why is a planned independent requirement not consumed against a customer requirement even though it is in the consumption period? Ques tion: What are commo n reasons for the reductio n not occurrin g? This view is highly customizable to tailor for an individual situation.

0 thoughts on “Planned independent requirements”