Wiring alternator diagram

We are commonly asked how to wire the Delco SI series alternators upon maintenance or upgrading from an older generator, wiring alternator diagram. While this series of unit often runs as a self exciting one wire, agricultural applications also used 3 wire connections to the alternator.

You may not have heard the word alternator but you might be aware of the word alternating current or AC. Alternator allows you to convert mechanical energy into electrical energy especially in motor vehicles. An alternator wiring diagram will help you get the basic know-how of the circuit and how the components are linked together in a circuit. So, without further ado, let's dive in. Do you want to know more about what is alternator wiring diagram and how to make your own alternator wiring diagram?

Wiring alternator diagram

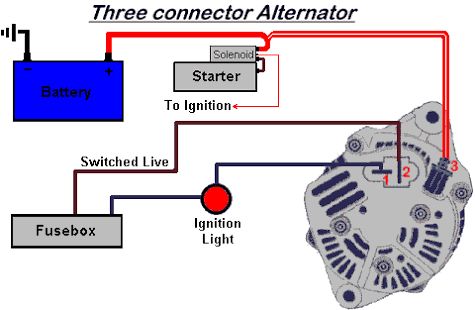

In the automotive world, data, knowledge, and information cannot be overlooked. Ensuring each component, from rotor to rectifier, functions optimally is our specialty. Dive with me into the intricacies of the 3 Wire Alternator Wiring Diagram in this article. A 3 wire alternator wiring diagram is a comprehensive representation of the components connected to an alternator, as well as their connections. It shows the existence of three wires connecting to the alternator, with all other connected parts labeled distinctively in different colors. A proper alternator wiring diagram should include color designations for each component; for example, low-resistance cables may be blue or yellow, and battery cables could be white or red. In addition, key components such as fuses and relays can easily be located by referring to a corresponding schematic in the wiring diagram. With careful study, understanding a 3 wire alternator wiring diagram need not be overly complicated, making it simple to quickly diagnose any electrical issues arising from this critical component. You may be also interested in: What color is the ignition switch wire? A 3 wire alternator wiring diagram is composed of several components. The most basic and important part is the red wire, which connects to the battery-positive terminal. In addition, there are often auxiliary wires used for powering accessories like headlights, as well as other options such as a tachometer connection or voltage regulator cables. In some cases, it may be necessary to unscrew certain components or remove plastic shields in order to access the alternator wiring. When connecting the wires, it is important to ensure that all connections are done properly and securely, with no loose wires.

After testing, turn off the ignition and finish installing any other necessary hardware such as mounting brackets or covers.

Edit Online. It generates electricity, provides electrical supply to vehicles, and recharges the battery. The alternator works by converting mechanical energy into electrical energy from alternating current to the direct current. The primary function is to work jointly with the battery to supply energy to the electrical components, i. It changes the alternating current into a direct current and regulates the voltage to meet the required minimum power for each unit. This is a three-wire alternating wiring diagram showing the connections between the different components. The circuit comprises three main wires: battery positive cable, voltage sensing wire, and ignition wire.

It ensures an efficient conversion of alternating current from the alternator to direct current for your battery, harmonizing the electrical demands of any car, whether Ford or Chevrolet. From my extensive experience diving into various electrical systems, the importance of understanding the intricacies—such as rotor functions, field coil roles, and the distinction between ground wires—is clear. Information, data, and knowledge cannot be ignored. With my expertise, I feel an urgency to guide others through this complex realm. An alternator, at its core, is more than just an essential component under the hood. An alternator not only provides your car with the bulk of its electricity but also plays a pivotal role in recharging the battery. This rotation, combined with the magic of the serpentine belt, generates electricity. In technical terms, the alternator converts mechanical energy to electrical energy with an alternating current AC. This AC, when it passes through a magnetic field, is then converted to direct current DC through diodes. Understanding Alternator Power Output is a dance of numbers and currents.

Wiring alternator diagram

We are commonly asked how to wire the Delco SI series alternators upon maintenance or upgrading from an older generator. While this series of unit often runs as a self exciting one wire, agricultural applications also used 3 wire connections to the alternator. If you are looking for the no charge indicator light on the dash to function as well, this should help determine which connection to use. The ignition switch is most commonly powered from the starter battery stud, but source may vary depending on application. With key on power is then transferred through the no charge indicator light to the 1 spade on the alternator regulator connection. Depending on switch circuitry there may also be a diode before the 1 spade to prevent the current when charging from back feeding the ignition switch and not allowing unit shut down. The third spade connection in this diagram is optional and will not be present on all units. This is one of the three phase connections and is most commonly used to function electronic tachometers. This connection is not necessary for unit to function even if it is present.

Thredup

Below given are some alternator wiring diagrams that are used for different purposes. This is the most important step in installation and requires a bit of knowledge about electrical systems. With proper maintenance, this unit should provide reliable power for many years to come. Electromechanical regulators coil the voltage sensing cable into an electromagnet. Allison Lynch Originally published Dec 26, 22, updated Jul 26, The functioning of an alternator is straightforward. Unlike the one-wire alternators, they can generate and rectify electricity in one circuit. As a result, the system output is changed to adjust the needs of the system. The 1 regulator connection must be off with ignition off to prevent battery drain. You may not have heard the word alternator but you might be aware of the word alternating current or AC.

Knowing how to read and decipher a wiring diagram is essential for anyone who works on automobiles regularly. This guide will provide a basic overview of how to use a Lucas 15 ACR alternator wiring diagram, so that you can easily follow along with the diagrams when working on your own vehicle.

The primary function is to work jointly with the battery to supply energy to the electrical components, i. Read more: Color coding Ford wire harness color code. Free Download. When connecting the wires, it is important to ensure that all connections are done properly and securely, with no loose wires. In some cases, it may be necessary to unscrew certain components or remove plastic shields in order to access the alternator wiring. Add a comment. Carefully remove it from its mounting location and set it aside for disposal. The functioning of an alternator is straightforward. The alternator works by converting mechanical energy into electrical energy from alternating current to the direct current. We are commonly asked how to wire the Delco SI series alternators upon maintenance or upgrading from an older generator. Before beginning installation, be sure you have all the tools needed to complete the job.

In it something is. I agree with you, thanks for the help in this question. As always all ingenious is simple.