Weight of plywood 4x8

Not all plywood sheets are made equal, and the weight can vary greatly depending on the type of plywood used. This article will provide a detailed guide on plywood weight and present a chart boredpanda help you select the right plywood for your project. Weight of plywood 4x8 is reader-supported. When you buy through links on my site, I may earn an affiliate commission at no extra cost to you.

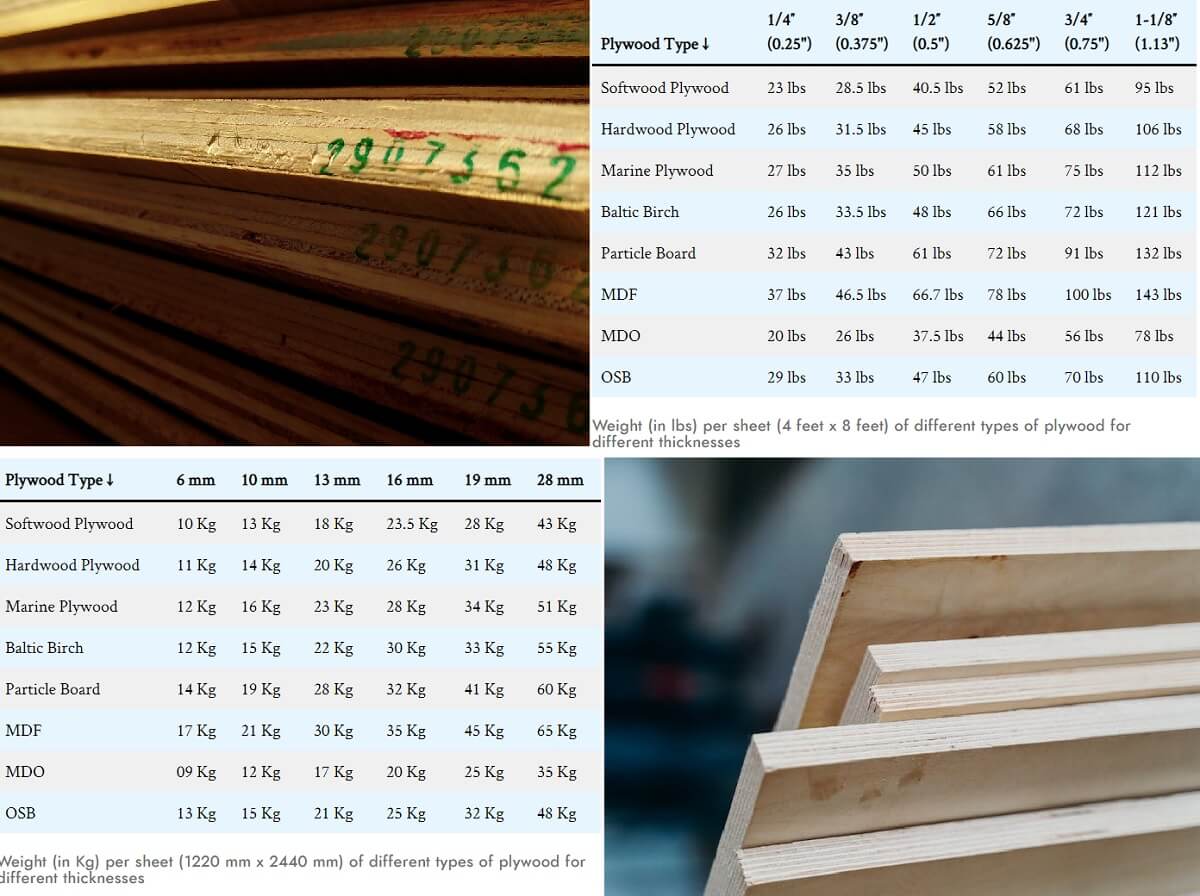

The actual weight of plywood varies by product and manufacturer, which can make it challenging to predict the weight perfectly. A few factors impact the weight of plywood. The precise thickness of the panel is a major factor in the weight. The actual thickness of plywood is almost always thinner than the advertised nominal thickness and varies from product to product. In addition to thickness, the type of plywood is a major factor in how much it weighs. Different species of wood have varying densities.

Weight of plywood 4x8

Equal thickness okoume veneers each layer, Light weight, Strong. This plywood is used to make everything from: Kayaks to " yachts, Custom cabinets to toys. You can varnish, stain, paint, fiberglass and Formica this material. The 1. Sapele wood every layer, Equal veneer thickness, Extremely Strong, This material is generally finished bright. Minimum 1. Whole piece rotary cut face, Fir wood every layer, Football patches on both faces, This material is used when appearance is not important. Khaya Mahogany A1. Flat sawn African mahogany face and back, Tropical hardwood core, This is decorative marine plywood, Best used when appearance is important. Looks like genuine Honduras mahogany. African ribbon stripe Sapele Mahogany A1. Quarter sawn African mahogany face and back, Tropical hardwood core, This is decorative marine plywood, Best used when appearance is important. White Ash A1. Flat sawn Select white ash face and back, Tropical hardwood core, This is decorative marine plywood, Best used when appearance is important.

Pressure-treated plywood uses relatively more adhesive than other plywoods. Plywood Type Plywood Thickness 6mm 9. The hardwood veneers improve strength, stability, and impact-resistance.

Other engineered wood panel types, such as particle board or OSB, contain a much higher percentage of adhesive resin, and since these resins are heavier than wood, these panels tend to be significantly heavier than plywood. Plywood weight is determined by the length, width, and thickness of the panel, as well as the wood species and the types and amounts of adhesives, primers, and sealants used to make the plywood. This goes for all other types of engineered wood panels as well. Plywood, OSB, particle board, etc. Some of these panel types require quite a bit more of these materials than other types. Since adhesive resins and sealants are much heavier than wood, this means that wood products that use a lot of them will be heavier than wood products that use less of them. Another factor in plywood weight is the wood species used to make the panel.

The actual weight of plywood varies by product and manufacturer, which can make it challenging to predict the weight perfectly. A few factors impact the weight of plywood. The precise thickness of the panel is a major factor in the weight. The actual thickness of plywood is almost always thinner than the advertised nominal thickness and varies from product to product. In addition to thickness, the type of plywood is a major factor in how much it weighs. Different species of wood have varying densities. For example, hardwood lumber weighs more than softwood lumber due to higher densities. You can calculate the weight of different species of lumber using our lumber weight calculator to get an idea of how much different lumber species might impact the weight. With that said, most hardwood plywoods use softwood layers for the inner plies and hardwood veneers only for the outer surfaces.

Weight of plywood 4x8

The plywood weight calculator below will help estimate the total weight of any size and any type of plywood product. Check out the lumber weight calculator to estimate lumber weights and the log weight calculator to calculate green log weights. Just a heads up, this page contains affiliate links. If you buy through them I earn a small commission. If you chose to buy through these links I truly thank you for your support! These densities can vary significantly from manufacturer to manufacturer, due especially to different wood species, layups, glues, and moisture contents. When entering the thickness, remember that the actual thickness of the plywood can be slightly different usually thinner than what it is sold as.

Happy wife happy life gif

The plywood thicknesses we include cover most of the standard panel thicknessess available from engineered wood panel manufacturers today. This makes it important to analyze the weight of the plywood, as weight considerations are crucial for buoyancy, load distribution, and fuel efficiency. The use of MDO for sign boards is very common. CDX plywood , the most common plywood used for roof sheathing, is a grade of softwood plywood. It is one of the heaviest forms of engineered wood panels due to its extremely high resin content. Safety precautions that must be followed while working with plywood include: wearing safety glasses, anti-cut gloves, and masks to avoid inhaling the dust generated when cutting plywood. Other engineered wood panel types, such as particle board or OSB, contain a much higher percentage of adhesive resin, and since these resins are heavier than wood, these panels tend to be significantly heavier than plywood. The following tables provide typical weights dead load , self-weight for plywood, OSB, and other engineered wood panels according to thickness and panel type. Use our plywood calculator to find how many sheets of plywood you need for your project. It is generally the lightest type of engineered wood panel, due to the light weight of the wood species used and the relatively low amount of adhesive used in the manufacturing process. Since adhesive resins and sealants are much heavier than wood, this means that wood products that use a lot of them will be heavier than wood products that use less of them. What Affects the Weight of Plywood A few factors impact the weight of plywood.

Plywood is an engineered or manufactured type of wood used for everything from walls to furniture.

But how heavy is a sheet of plywood? Final thoughts Frequently asked questions FAQ. In addition to using different amounts of glues and resins, different types of resin vary in weight. When precision is necessary, always refer to the specification sheet for the actual, specific product you intend to use, or contact the technical department of the panel manufacturer. The actual thickness of plywood is almost always thinner than the advertised nominal thickness and varies from product to product. You can also find mixed-grade plywood with different-grade veneers on either side. The 1. The weight of a plywood sheet may vary based on factors such as its thickness, size, and type of wood. These high-quality plies serve to keep moisture out of the panel, making it perfect for outdoor applications where moisture resistance is of utmost importance. Because of the extremely high resin content, MDF tends to be one of the heaviest types of engineered wood panels. Comments The comments are closed. Because of this and the fact that the southern yellow pine used is much heavier than other wood species used in construction, pressure-treated plywood tends to be a heavy plywood. Flat sawn Select white ash face and back, Tropical hardwood core, This is decorative marine plywood, Best used when appearance is important. APA Plywood Standard : The Engineered Wood Association formerly the American Plywood Association provides standard notional plywood weights for use in determining expected dead loads when performing structural engineering calculations.

I not absolutely understand, what you mean?