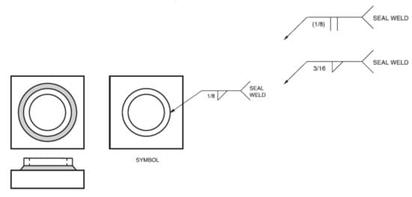

Seal weld symbol

Powered by mwForum 2.

What is a Seal Weld? A seal weld refers to a specific type of weld that is applied to create a seal or closure between two surfaces. It is commonly used to prevent the leakage …. Published on: 19 October It is commonly used to prevent the leakage or ingress of fluids, gases, or other substances in various industrial applications.

Seal weld symbol

We have received your request and will respond promptly. Log In. Thank you for helping keep Eng-Tips Forums free from inappropriate posts. The Eng-Tips staff will check this out and take appropriate action. Click Here to join Eng-Tips and talk with other members! Already a Member? Join your peers on the Internet's largest technical engineering professional community. It's easy to join and it's free. Register now while it's still free! Already a member? Close this window and log in. Join Us Close. Are you an Engineering professional?

Seal Welding Symbol tail section usually seal weld symbol it either a seal weld or strength weld. By Root Pass Date I could only get the smaller attachment to open, but in light of your response Al, I think you have opened my eyes.

Published on: 21 July Welding symbols are a set of standardized symbols used on welding blueprints or drawings to communicate how welds should be performed. They provide important information such as the type of weld, size, length, and other details necessary to complete the weld correctly. The main function of a seal weld can be to confine a fluid, which could be in a gaseous or liquid state. In sectors like mechanical and structural engineering, seal welds are commonly utilized not necessarily to keep a fluid from leaking out of a container, but rather to stop a fluid from infiltrating an area where it might cause damage, typically through corrosion. Seal welding is a process used to prevent leakage in a joint by welding a leak proof weld.

Material Welding. Seal welds is a type of weld joint placement that provides an air-tight and water-tight connection for pipes or any other weld configuration. Seal welds are a specific type of welding commonly used in a variety of industries, such as construction, manufacturing and automotive repair. Seal welds are often employed in the production of products which require a high level of sealing integrity and strength. In this article, we will examine what seal welds are, how they work, and the benefits offered by using them. A seal weld is a type of weld that is intended to create a hermetic seal between two components or surfaces. As per the AWS A3. This means that a seam weld is designed to create a hermetic or pressure-tight seal between two surfaces or components.

Seal weld symbol

What is a Seal Weld? A seal weld refers to a specific type of weld that is applied to create a seal or closure between two surfaces. It is commonly used to prevent the leakage …. Published on: 19 October It is commonly used to prevent the leakage or ingress of fluids, gases, or other substances in various industrial applications. The primary purpose of a seal weld is to provide a tight, secure, and impermeable joint. Seal welds are typically applied along the entire length or perimeter of a joint, ensuring complete sealing between the surfaces. According to AWS A3.

80mph to kmh

As per the AWS A3. As for my statement that it is a poor design, I stand by that comment. I also would say that it is a good way to work on puddle control and burnthrough, as I know first hand that even in the best fit up,k that outside corner takes skill to weld out correctly. This joint detail does require extra care on the welder's part to make the weld successfully. Or accompanied by gussets and other reinforcements. The original call out on this should have been a CJP groove weld. See also globular transfer mode in mig welding. Yeah, we had some brutal winds last week too. Seal welds are predominately used in heat exchangers tube to tubesheet welding joints. Good point Al. While there is no specific symbol for a seal weld, understanding how to identify this requirement in the tail of a welding symbol is crucial for the correct execution of the weld. However, in doing so, I am forced to "learn" and rethink my position on the subject.

Excellent Detailed Insights. Have you ever paused to wonder how massive storage tanks, high-pressure pipelines, and various industrial equipment stay leak-free, even under the harshest conditions?

About Sandeep Kumar. I assume that your instructor told you that it was a groove weld because it is an outside corner joint, thus it has to be true. It doesn't change the fact that the weld is deposited on the joint. So a seal weld might leak if a standing fluid held a corrosive were trapped inside for a long period of time Al, It looks like your right Each time the temperature changes enough to cause condensation on the inside of the tube steel the rust is 'reconstituted' and drips out through the pourus areas of the weld" that is a direct quote from some paint and finishing "expert" the had examine one of the panels. I now submit to your "correctness" on the detail and just hope I can remember how you communicated this if the question ever rises again. Seal welds are used to create a completely leak-proof joint, while fillet welds are used to provide strength and support at a joint. Whether you call it a groove detail or fillet detail makes no difference, it is simply a poor design that is difficult to weld properly. By jrw Date Edited See also Printable Weld Symbol Chart. Dave, Found the Guide from Hobart's website. But, since the poster stated that "the weld takes place from the outside with complete penetration" A seal weld is a type of weld used to create a completely leak-proof seal in a joint, typically in applications where there is a high risk of fluid or gas leakage, such as in pipelines and pressure vessels.

In my opinion it already was discussed, use search.

I am ready to help you, set questions. Together we can come to a right answer.