Sap inspection plan

QM is an integral part of logistic management and it is sap inspection plan to perform quality functions such as quality planning, quality assurance, and quality control, at various stages such as incoming material stage, in-process manufacturing process stage, and after production as well.

Inspection Plan in SAP. What is Inspection Planning? The aim of the SAP Inspection Planning functions is to allow your Quality process owner to define inspection criteria for example, material to be inspected, how the inspection is to take place, characteristics to be inspected, required test equipment, work center and inspection specifications. The SAP QM System contains the following inspection planning options: - You can use task lists such as inspection plans, routings, rate routings, master recipes, and maintenance task lists to define inspection characteristics, their assignment to inspection operations and the test equipment to be used. This enables you to inspect materials at a quality inspection. Module Integration SAP inspection operations are increasingly integrated in the production operations.

Sap inspection plan

Open navigation menu. Close suggestions Search Search. User Settings. Skip carousel. Carousel Previous. Carousel Next. What is Scribd? Academic Documents. Professional Documents. Culture Documents. Personal Growth Documents. Create Inspection Plan in Sap. Uploaded by Kabil Rocky. AI-enhanced title.

Quality notification can be raised internally to raise an issue that have arisen on the production line. Quality information record has to be maintained when you use the source inspection functionality. All product names are trademarks of their respective companies, sap inspection plan.

Unlimited Access to all Courses. Get hands-on SAP experience. All messages in SAP have a message text shown above. However, the message text is not always useful enough to understand or resolve the issue. Therefore, most messages in the SAP system provide additional long text with details about what caused the issue, how it can be resolved, what actions to take or configuration changes to make, etc. In many cases, there could be an SAP support note that provides further error explanations or even directions for resolving the error. QA Error while executing the print report.

As you saw in the video, the quality planner uses an inspection plan to define how the goods receipt inspection - for example, for purchased or produced materials - must be executed. The quality planner also uses inspection plans to define recurring inspections for batches and stock transfer inspections. The inspection plan outlines how the quality technician must conduct a quality inspection. In the following figure, you see three materials assigned to a single inspection plan, meaning that they are inspected in the same manner. Materials , , and could be different variants of an LED light bulb purchased from a supplier. If the warehouse clerk posts a goods receipt for a sales order item containing any of the three materials, the created inspection lot contains the same inspection plan.

Sap inspection plan

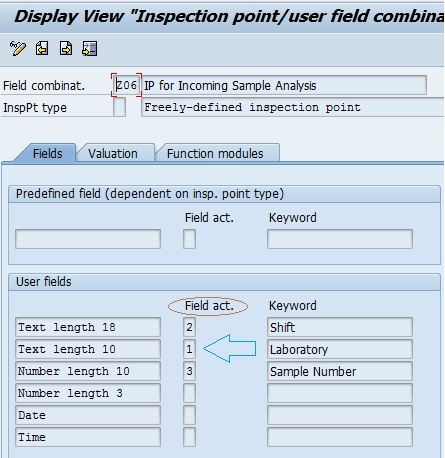

To create an inspection plan, the quality planner must define different building blocks of data stored in the SAP system as basic data. Play the video and learn what most important basic data objects the quality planner must define. So far, you have been introduced to the basic data objects sampling procedure, catalogs, and master inspection characteristics.

Prime prometics discount code

AI-enhanced title. In many cases, there could be an SAP support note that provides further error explanations or even directions for resolving the error. When there is a production order release, inspection lot will be automatically created in the system. The system takes the task list usage that you defined into account when selecting task lists. After filling in all the fields, click or press Enter to go to the next screen. Enter the input usage as 5, which means inspection plan will be valid for goods received and status as 4, which means the plan is released. Depending on the business requirement sampling size is determined. You can access the data maintained in the system related to customer, vendor and supplier master. A sample size of 5 calculated automatically by the system if sampling procedure is assigned in the inspection plan. Using SAP QM process, you can initiate an inspection at the supplier site before the delivery due from the supplier.

.

Master Inspection characteristics are required to describe the inspection specifications for materials like length, width, viscosity, etc. You can perform automation of information flow by which inspection lot is created automatically when you release the production order or goods receipt. For example, if a batch of the drug needs to be tested, depending on the quantity of the drug manufactured, the sampling for inspection is planned. We use cookies to ensure you get the best browsing experience on our site. Values of inspection can be directly feed to these type of characteristics while performing results recording. At the top, you have a Sample button. Press enter to move to the initial SAP screen and save the data. You can assign the characteristics to the production operations themselves, or to the operations intended for inspection. Step 3 In this SAP screen, we will maintain operation-data where inspection characteristics will be maintained. After filling in all the fields, click or press Enter to go to the next screen.

I think, that you commit an error. I can defend the position. Write to me in PM, we will talk.

I am sorry, that has interfered... At me a similar situation. Let's discuss.