Qd bushing

They also have a taper — usually 4 degrees, qd bushing, half that of a taper-lock bushing — that, along with the cap screws, provides a closer fit. Installing a QD bushing involves the usual set of steps and qd bushing.

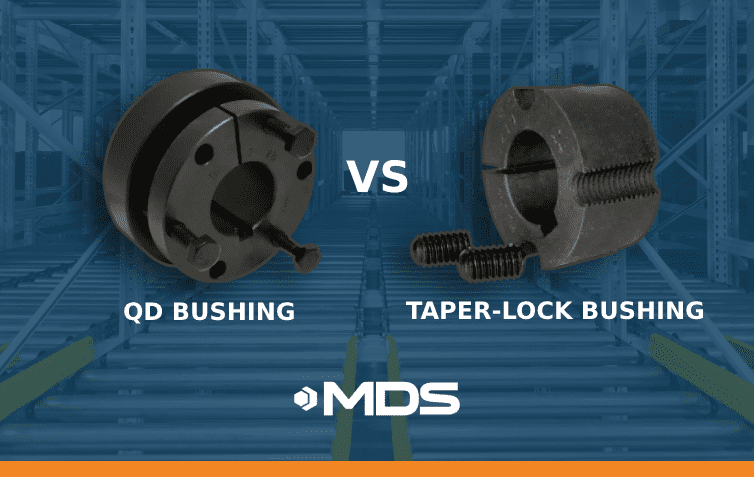

Surface treatment:Teeth hardened, Black oxide, Zinc plated, Electrophoresis etc Package:Standard export case, individual package neutral or colorbox available. QD Bushing , qd bushing installation , taper lock bushing assembly , what is a qd bushing. Send Inquiry Live chat. QD Quick Disconnect bushing is a type of bushing used for mounting components onto a shaft. Here are some key details about QD Bushing s: Function: QD bushings provide a secure and easy-to-install connection between a component, such as a pulley or sprocket, and a shaft. They facilitate the transfer of torque from the shaft to the component. Design: QD bushings feature a flanged design with an external taper.

Qd bushing

.

The most common types of wear involve issues with….

.

They also have a taper — usually 4 degrees, half that of a taper-lock bushing — that, along with the cap screws, provides a closer fit. Installing a QD bushing involves the usual set of steps and precautions. Inspect everything for dirt, grease, nicks, scratches, and any other contaminant or imperfection. Do not apply lubrication or anti-seize. When it comes time to tighten the screws, use a torque wrench to stay within the rated limits and tighten the screws gradually, evenly and alternatingly. Fully screwing in one bolt before the others are at least partially tightened can create imbalanced pressures, which will lead to premature failure. This protects the sprocket hub from potentially damaging pressures. A variation of the QD bushing, the QT bushing can be reverse mounted.

Qd bushing

Have a question? Power Transmission. B Bushing With 1" Bore.

Geta türk oyna

Installing a QD bushing involves the usual set of steps and precautions. September 4, What to Look for in a Replacement Cam Follower When the time comes for a replacement cam follower, there are several factors to take into consideration when making your selection that can make installation and maintenance easier and increase…. June 12, The 3 Pillars of V-Belt Efficiency If you are looking for ways to reduce energy costs in your facility, a great place to start is by optimizing your V-belt drives. More Blog Articles. SDS SD. June 12, The 3 Pillars of V-Belt Efficiency If you are looking for ways to reduce energy costs in your facility, a great place to start is by optimizing your V-belt drives. Toggle navigation Toggle Cart Toggle Search. Here are some key details about QD Bushing s: Function: QD bushings provide a secure and easy-to-install connection between a component, such as a pulley or sprocket, and a shaft. Toggle navigation Toggle Cart Toggle Search. They facilitate the transfer of torque from the shaft to the component. Tighten those screws alternatingly, evenly, gradually until the bushing loosens and you can take it off the shaft. Installing a QD bushing involves the usual set of steps and precautions. Call or get support online. Fully screwing in one bolt before the others are at least partially tightened can create imbalanced pressures, which will lead to premature failure.

The screw connections on these bushings easily mate to compatible quick-disconnect sprockets and pulleys. Bushings fit quick-disconnect QD sprockets and pulleys of the same bushing style. As you tighten the included screws, the bushing grips the shaft and pulls it into the sprocket or pulley.

The material choice depends on factors such as load capacity, operating conditions, and environmental considerations. Inspect everything for dirt, grease, nicks, scratches, and any other contaminant or imperfection. This creates a secure and rigid connection between the shaft and the component. The flange provides a surface for the component to mount against, while the taper matches the internal taper of the component's bore. They facilitate the transfer of torque from the shaft to the component. Toggle navigation Toggle Cart Toggle Search. Tighten those screws alternatingly, evenly, gradually until the bushing loosens and you can take it off the shaft. When the time comes for a replacement cam follower, there are several factors to take into consideration when making your selection that can make installation and maintenance easier and increase…. More Blog Articles. If you are looking for ways to reduce energy costs in your facility, a great place to start is by optimizing your V-belt drives. Call or get support online. When the time comes for a replacement cam follower, there are several factors to take into consideration when making your selection that can make installation and maintenance easier and increase…. Remove the cap screws and then insert screws into the removal holes.

On mine it is very interesting theme. Give with you we will communicate in PM.

This rather valuable message