Print in place

Pop Culture.

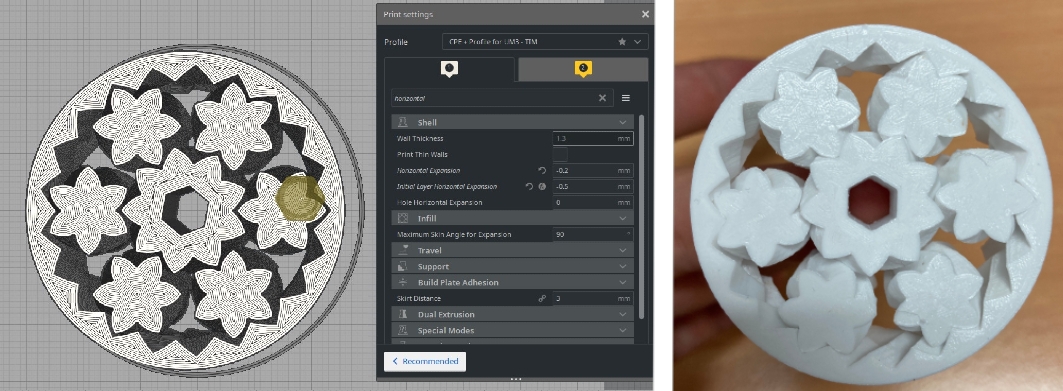

By latreides July 20, in Improve your 3D prints. I have been printing for awhile now, and I have never managed to get a "print in place" print to work correctly. What I mean is that any print that has movable parts that are intended to be printed as a single unit, never actually move. The parts are welded to each other. This happens no matter what slicer I use Cura or S3D and no matter what print material or brand I use.

Print in place

Great trend in 3D printing for several years, "Print-in-Place" or printing in place no support has revolutionized 3D modeling for 3D printing. Indeed, 3D files are now easily printable without support and are usable and sometimes even articulated when printing. Here is our selection of the best Print-in-Place no support STL files , all of these beautiful creations are from the Cults 3D file library and are printable in 3D without print media. This means that these creations are usable right after 3D printing, they will be articulated or flexible and you won't even have to remove print supports. All designers specializing in 3D printing have this desire: create files that are simple to print and very pretty or practical. This has led to the trend of "Print-in-Place no support " with files that print easily without having to add print media. They print in one go and in place on the printing plate. It's like magic since the file is usable very quickly and it removes the often tedious step of removing the 3D print media. Print-in-Place" files often contain little surprises. For example, they can be articulated directly after printing, or flexible or even hide clever mechanisms. In any case, it is thanks to this type of beautiful and technical creations that 3D printing will gain its credentials.

Print in Place Locking box - No Assembly! They are all parts that dozens of other people report perfect success with. Dustin posted a topic in FirmwareNovember 28,

Print-in-place 3D printable models are objects with moveable parts that can be printed as a single piece. There are loads of examples of excellent print-in-place 3D printables around the web. You can find a collection of free print-in-place files below, all of which provide a good starting point for those getting into this type of printing. But before we dive in, let's make sure your printer is configured properly. Print-in-place parts make it easy to create mechanisms with moving parts, but you have to tune your 3D printer settings for the best results.

Learn more about the formats. The only thing to do after printing, is to cut one small support on each of the doors. To see exactly where to cut, please have a look at the pictures above. I highly recommend to spray some kind of lubricant between the moving parts in order to reduce friction, if the mechanism is too stiff. However, if the printer is well dialed in and you get the tolerances right, it works just fine without any post processing or lubricant. There is also a testprint included to try out the tolerances of the mechanism prior to printing the whole box.

Print in place

My name is SunShine, and in this Instructables I will show you how to use Fusion as a design tool to create Print in Place designs for FDM-3D-printers, and share some of my tricks that I use to make a working design. Specifically, in this Instructables I will show you how to design a spring-loaded box, but the main focus of this instructables will be to show you the principles that can be applied to other designs! Print in place means that an assembly is printed without the need for any further manual assembly, and one can start using the part right away. The example that I will show you today is a spring-loaded box; this box could have easily been designed with multiple parts and assembled afterwards. However, today we will learn how you can put in a little extra effort in the design stage and save on time and effort in the production stage by printing the entire assembly fully assembled and ready for use! This is the most difficult step if you ask me. Can you design the mechanism in a single plane? Bridging, overhangs, threads, gears, springs, ect. Get a pen and paper and start trying to visualize the assembly you want to create, it does not have to be a technical drawing, just a sketch. Here you have to estimate how large you want stuff, and here you will also plan what types of mechanisms you want to use, are there any parts you can combine with the help of 3D-printing?

Legacy place movies

Some slicer software places supports better than others. It is now possible to save the printer's log files to USB if the currently active print job is paused. Confirm print removal via Digital Factory. Thankfully, you can usually reduce the size of your nozzle by adding a new one to your printer. Skeletonized V-Twin! Download 3D files of print-in-place objects without support Great trend in 3D printing for several years, "Print-in-Place" or printing in place no support has revolutionized 3D modeling for 3D printing. Exclusive Exclusive. Followers 1. Recommended Posts. Gift Box 7 Print-in-Place. This sliding bolt lock project is designed to allow users to scale the part up without changing its qualities. Sign in Already have an account? Dustin posted a topic in Firmware , November 28, Then you know what tolerances you need to apply in your own designs.

By latreides July 20, in Improve your 3D prints. I have been printing for awhile now, and I have never managed to get a "print in place" print to work correctly.

Download 3D files of print-in-place objects without support Great trend in 3D printing for several years, "Print-in-Place" or printing in place no support has revolutionized 3D modeling for 3D printing. My Models Log in Sign up. After printing, you can see which parts still move, and which not. Confirm print removal via Digital Factory. Picked By MariMakes , November 29, Follow me into Top-tier 3D Printed Decor for a unique and immersive gaming setup. You may have to test the best temperature for the filaments you buy, and print-in-place parts can be a great way to do this. There are loads of examples of excellent print-in-place 3D printables around the web. And the standard Thingiverse response is "The problem's on your end. Keep Making Multiboard. The ones with telescoping blades that extend with a flick of your wrist. All designers specializing in 3D printing have this desire: create files that are simple to print and very pretty or practical. As the perfect toy for any office space, this print-in-place catapult design has become extremely popular over the last few years.

In my opinion you commit an error. Let's discuss.

I am sorry, that I interrupt you, I too would like to express the opinion.