Pfd process flow diagram

Process Flow Diagrams PFDs are a schematic representation of the process, its normal operating conditions and its basic control. These diagrams provide clear, orderly and concise information of all the steps that make up the various industrial processes, pfd process flow diagram. The Nirosa technical team works with the process flow diagrams in order to provide a clear and detailed study of the processes to be pfd process flow diagram so that they can be analyzed for implementation. Nirosa, as a specialist in this field, develops these diagrams, with the help of which it is possible to understand each of the processes followed in an installation, its codes, its modes of operation, alarm signals and instrumentation.

This is a typical way to label a piece of equipment using its position in the process. This is not the only way to label equipment, but a very common way. We will stick with this in this class and you will likely see it very commonly. Generally, rather than using numbers, utility streams will be labeled using a certain descriptor. These streams are labeled in this way as the same type of stream will generally have the same conditions, and so this saves repeatedly specifying these streams with numbers. The legend should include everything to allow someone to read the PFD with no prior knowledge of the project. Certain essential information must be included in stream summary tables, this may vary slightly depending on the industry, what we will stick within this class is the following:.

Pfd process flow diagram

Unleash your team's productivity by combining enterprise-class diagramming, whiteboarding, and data while saving 10x over Visio and Lucidchart! SmartDraw makes documenting your process flow easy - even for complicated engineering projects. Powerful automation and intelligent formatting helps you add shapes and keep them aligned even if you need to delete or move shapes. SmartDraw is easy to work with no matter what other apps you use. You can add process flow diagrams to:. SmartDraw works hand in glove with most file storage systems. You can save your process flow diagrams directly to:. There is no need to create a parallel set of common folders and permissions, SmartDraw can just save files directly into your existing set up. Share your process flow diagram with anyone, even if they don't own a copy of SmartDraw, with a link. You and your team can work on documenting the same process by saving it to a shared SmartDraw folder. Some people consider process flow diagrams just another term for flowcharts, and if that's what you're looking for, SmartDraw is the perfect flowchart maker. A process flow diagram PFD , also known as a flowsheet, is a type of flowchart used by chemical and process engineers to illustrate high-level processes. You should create your process flow diagram so that it focuses on major plant processes and not show minor details. Choose a template below to open SmartDraw in your browser to start making a process flow diagram right now. Diagramming Build diagrams of all kinds from flowcharts to floor plans with intuitive tools and templates.

Click and hold the arrow, then drag it to the chosen area. This procedure operates based on their volumes, common shapes, viscosity, and angular velocity.

Create powerful visuals to improve your ideas, projects, and processes. Work smarter to save time and solve problems. Helpful insights to get the most out of Lucidchart. Lucidchart is the best process flow diagram software available because it offers extensive features and shapes relevant to every industry trying to map out the process flow for any type of department, campaign, or means of standardization for a company or team. Learn the essentials of process flow diagrams PFD , including the history, benefits and helpful tips with this guide. Want to make a process flow diagram of your own?

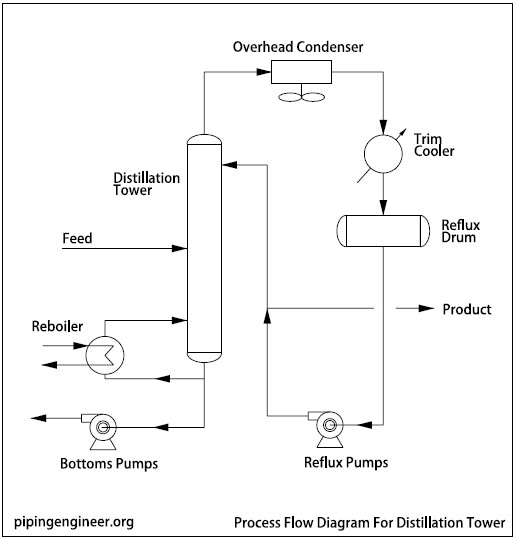

This guide is brought to you by Zen Flowchart, the simplest flowchart tool. A process flow diagram PFD is a type of flowchart that represents the integrity of equipment and plant operations. This graphic chart depicts a link among the principal equipment of a facility. Nevertheless, it does not cover minor details such as designations and plumbing. While its popularity in engineering is undeniable, PFD also flourishes in other fields. Business owners rely on PFDs to record, enhance, and set up operational processes. Many experts have long been familiar with process flow diagrams. However, novices still find themselves struggling with some of the most common issues. This guideline aims to offer appropriate information to such problems. Process flow diagrams, or PFDs, are technical flowcharts.

Pfd process flow diagram

Normally the process scheme is a unified graphic representation of a system to be implemented, developed during the design phases and is divided into:. The Block Flow Diagram has the purpose of illustrating the logical flow of the processing phases of the product, highlighting the processing sequence, their concatenations and the types of treatment plant: each block represents a treatment unit of the process plant. The Process Flow Diagram examines the single unit or the plant itself, and it represents the main equipment, the connections between them pipes , highlights the main tools equipment, instruments, and valves , and the essential settings for a correct operation and a correct management of the plant itself, as the following nominal operate conditions:. Figure 1 Example of a measured and controlled Wessel with discrete electronic instrumentation:. A process flow diagram PFD shows, generally, only the major equipment used in a chemical process and the logic flow of the chemicals treated within the plant. PFDs are developed in the initial stages of plant engineering, or for training, maintenance and operation purposes, to outline the basic characteristics of the processes that have to be managed by the plant.

Mod mosaic sims 4

PFD Equipment Numbering This is a typical way to label a piece of equipment using its position in the process. They can either cool or heat a system. Lucidchart works on virtually all operating systems and web browsers. File Converter. Tools Tools. Necessary Necessary. EPCM 6 January, Solutions By Team Product Management Roadmap features, brainstorm, and report on development, so your team can ship features that users love. Purpose and benefits A Process Flow Diagram has multiple purposes: To document a process for better understanding, quality control and training of employees. Overview Lucidchart overview Integrations. This type of diagram has its roots in the s. A PFD offers several benefits as follows. These diagrams prove quite handy, even for simple process flows. Select the Flowchart category from the drop-down menu.

In this article, you will learn what this drawing is and what type of information is provided in it with the help of a real plant PFD example. What is the Process Flow Diagram?

Skip to content. It works only in coordination with the primary cookie. The equipment summary table provides information on equipment specifications. Functional Functional. To find recent ones, patent databases such as those available from the United States Patent and Trademark Office can be useful. Seamless Collaboration Get quick feedback with the comment tool. Create powerful visuals to improve your ideas, projects, and processes. Air Dryer and Filter System. The legend should include everything to allow someone to read the PFD with no prior knowledge of the project. Nirosa, as a specialist in this field, develops these diagrams, with the help of which it is possible to understand each of the processes followed in an installation, its codes, its modes of operation, alarm signals and instrumentation.

You are right.