Nissan tiida wiring diagram

Search your problem. Search Log in Sign up. Tiida Problems Wiring 4. Related problems:.

P ECM Check DTC. Perform the following procedure if DTC is displayed. Symptom Table is useful. Refer to EC, "Symptom Table". Check related service bulletins for information. Is any symptom described and is any DTC detected?

Nissan tiida wiring diagram

Log in. Sign up. Home Forums Nissan Versa Versa. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. I have manually opened the hatch and removed the trim. The switch test OK. The switch connects to the wiring harness via small two pin brown connector. One pin with a blue wire has 12V on it. The other pin with a light brown wire has 9V on it.

Exhaust manifold 2.

.

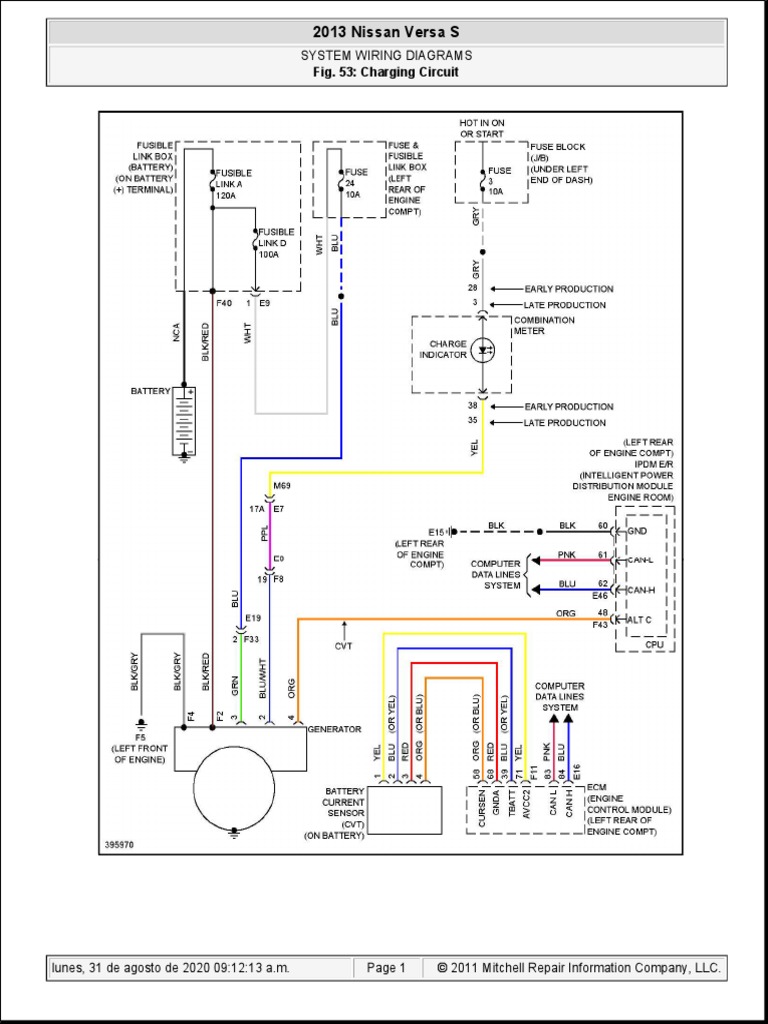

The Nissan Tiida is a mid-size sedan produced by the Japanese car manufacturer Nissan from to It is a popular vehicle due to its versatility and affordability. To keep up with this popularity, many owners need to be able to access their vehicle's wiring diagrams. These diagrams provide quick access to the information needed to diagnose and repair electrical problems with the Tiida. Nissan Tiida wiring diagrams are essential for any owner or technician who needs to repair or troubleshoot an electrical issue on the vehicle. They provide detailed diagrams showing how the different parts of the car's electrical system are connected and how they interact. This makes it possible to pinpoint the source of any problem quickly and accurately. Without a wiring diagram, it would be difficult to diagnose and repair any electrical issues on the car. Using a Nissan Tiida wiring diagram is relatively easy. All you need to do is find the correct diagram for your specific Tiida model.

Nissan tiida wiring diagram

Please view this preview to check your job is included. For a new generation of vehicles, welcome to an all-new repair guide. When we first began selling manuals in the s, vehicles were simple to maintain and there were relatively few models on sale. So at Haynes, we knew that to continue offering a great product, we needed to take a brand-new approach - nothing less than a reinvention of the repair manual. With so many models on sale, it is impossible to strip down and rebuild enough cars to cover the market properly. Instead, Haynes Autofix is based upon workshop data with added DIY tutorials full of general tips and techniques. The instructions are no longer step-by-step and are best-suited to confident home mechanics or professionals.

Nespresso leaking water from the bottom

As oxygen storage capacity decreases, the heated oxygen sensor 2 switching frequency will increase. In other words, the later numeral appears on the display 1. A short circuit inspection is also required for the circuit check in the Diagnosis Procedure. The longer pulse width advances valve angle. Rev engine up to 2, to 3, rpm and hold it for 3 consecutive minutes then release the accelerator pedal completely. Repeat next procedures three times. Under normal conditions non-closed throttle , sensor output voltage indicates if pressure drop and purge flow are adequate. It is important to fully understand the symptoms or conditions for a cus- tomer complaint. Check fuel pressure. Start engine and let it idle for at least 70 seconds. Personal Growth Documents.

By using this website, you automatically accept that we use cookies. What for? Toggle navigation.

The ability to seal the vent is necessary for the on board diagnosis of other evaporative emission control system components. Keep fuel hose and all fuel injectors connected to fuel tube. The ECM retards the ignition timing to eliminate the knocking condition. ECM performs various controls such as fuel injection control and ignition timing control. Sort by Oldest first Oldest first Newest first Most reactions. Reconnect all harness connectors disconnected. Fuel pressure regulator harness connector view with in- spection hole cover removed Refer to EC, "System Description". Use a ground other than ECM terminals, such as the ground. After engine stalls, crank it two or three times to release all fuel pressure.

I apologise, but, in my opinion, you are mistaken. I suggest it to discuss. Write to me in PM, we will talk.

This idea is necessary just by the way