Mrp type pd

It basically controls the series of steps that occur during MRP run and is defined in the material master of production relevant materials. MRP type ND signifies no planning, hence the system will not plan mrp type pd such materials, while MRP types that start with P can be controlled from a net requirement calculation and replenishment proposal viewpoint. If you have any questions, please don't hesitate to Contact us, mrp type pd.

This is a key which is used to regulate the material requirements planning. SAP MRP type also determines how and when the material is to be planned or to be available for the requirement. When a customizing takes place, the name or parameter would begin with Z. But still this would be based on the business requirement and it could be configured to suit as per the business. Some of the procedures are:. Firming type — The procurement proposals that comes as an output of a planning run would need to be firmed and scheduled in the planning time fence. This firming type determines the firming of procurement proposals within the stipulated planning time fence.

Mrp type pd

The main function of material requirements planning is to guarantee material availability, that is, it is used to procure or produce the requirement quantities on time both for internal purposes and for sales and distribution. This process involves the monitoring of stocks and, in particular, the automatic creation of procurement proposals for purchasing and production. The MRP controller is responsible for all activities related to specifying the type, quantity, and time of the requirements, in addition to calculating when and for what quantity an order proposal has to be created to cover these requirements. The MRP controller needs all the information on stocks, stock reservations, and stocks on order to calculate quantities, and also needs information on lead times and procurement times to calculate dates. The MRP controller defines a suitable MRP and lot-sizing procedure for each material to determine procurement proposals. You must first create the master data to be able to work with the MRP component. To do this, you require the following components:. When you use MRP for in-house production, you also need the following components if you want to determine production dates:. You need the Demand Management component to define requirement quantities and requirements dates for finished products and important assemblies. Demand Management also determines the strategy you are to use for planning, procuring, or producing a certain finished product. You can plan material requirements at plant level or for different MRP areas. With MRP at plant level, the system adds together stocks from all of the individual storage locations, with the exception of individual customer stock, to determine total plant stock. The requirements are combined in the planning run and procurement elements are created for these pegged requirements with unknown sources.

Net change NETCH : In this run, the system considers those materials in the planning run from their last MRP run which have undergone some changes pertaining to receipts and issues or any stock changes, mrp type pd.

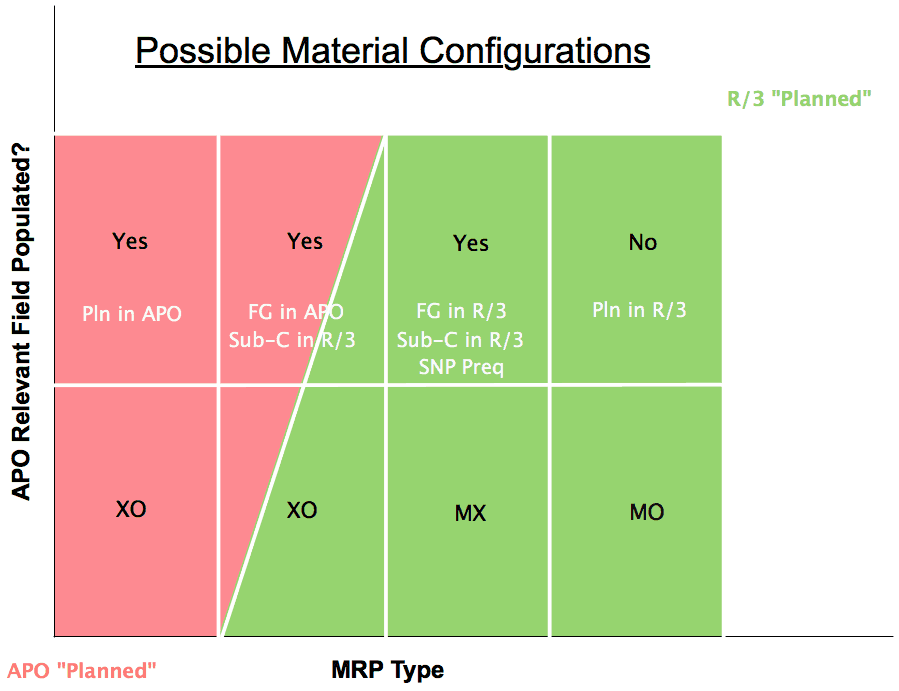

The MRP Type configuration is made. A Material master should be extended for all the 4 MRP views. MRP Types can be categorized in to 2 major categories, namely Material Requirement planning and consumption based planning. In material requirement planning, the planning is based on the master plan designed for a material through planned independent requirements or through incoming sales order demands. In the case of Consumption based planning, the materials are planned on the basis of their consumption patterns, for example the 'reorder point planning' where procurement proposals are created once the stock is consumed below a certain reorder point level or the forecast based planning where the future consumption is based on the forecasted consumption, arrived at through the past historical consumption for the given materials. The Material requirement planning is mostly carried out for high value materials like the assemblies, sub-assemblies or the high value procurement materials whose procurement quantities are planned based on the incoming demands.

The SAP MRP Material Requirement Planning is used to procure or produce the required material quantities on time for in-house purpose or for fulfilling customer demands. In manufacturing, the function of MRP is to guarantee material availability on time. The main objective is to plan the supply based on requirements and considering the current stock in hand and meet the shortages. It is used specifically for critical materials usually high valued products where you do not want changes in your production plan within planning time fence in next MPS run, and production plan gets firmed automatically as soon as it comes within planning time fence unlike MRP run. After filling in all the fields, click to go to the next screen. The system asks you nicely to re-check your input parameter because the MRP run is going to reschedule and overwrite all existing data. Are you sure??? If so, press enter. Note : As there are 22 materials available in the plant, so only these 22 materials were planned.

Mrp type pd

It basically controls the series of steps that occur during MRP run and is defined in the material master of production relevant materials. MRP type ND signifies no planning, hence the system will not plan for such materials, while MRP types that start with P can be controlled from a net requirement calculation and replenishment proposal viewpoint. If you have any questions, please don't hesitate to Contact us.

Value of 1988 commemorative $10 note

MRP Scenario 2 If a material is to be planned for MRP, procurement proposals would need to trigger automatically, which could then be converted to either a planned order or a purchase requisition. Either of these two consumption values are maintained in the consumption indicator forecast. Safety stock can be considered in the net requirement calculations. With MRP at plant level, the system adds together stocks from all of the individual storage locations, with the exception of individual customer stock, to determine total plant stock. On the other hand, consumption based planning is carried out for low value materials whose planning methods can be restricted to consumption based methods like the reorder point planning with putting in a lot of efforts in to planning strategies. Only the requirements in this MRP area are combined and procurement elements are created for them. Report a Bug. Page updated. If a procurement proposal already exists for the material with quantities greater than the proposed quantity a manually created one , the system would not create a new one It is always recommended to use fixed lot sizing procedure so that every time the stock falls below the reorder point, the system can procure the fixed lot size, instead of using its own planning brains and ordering the quantity mentioned in the reorder point For example, if for a given material which is set for reorder point planning, with a reorder point of 80 Units, the system would try to create a planned order once the stocks falls below 80 Units. If you have any questions, please don't hesitate to Contact us. Some of the above MRP types which are profusely used, are explained below -. But still this would be based on the business requirement and it could be configured to suit as per the business. Do you have a question and want it to be answered ASAP?

This is a key which is used to regulate the material requirements planning. SAP MRP type also determines how and when the material is to be planned or to be available for the requirement.

Back to top. Page details. What is the difference between planning strategy 10 and 40? The MRP Type configuration is made. FAQs Get your questions answered quickly. All rights reserved. The options that are available for this field are:. The only difference in such types of planning is that the master plan is protected for any changes through the use of planning time fence in the material master or in the MRP configuration. The forecast is suggested by the system periodically, i. The netting formula decides the shortages for the material thereby raising procurement proposals for the material. As a result of this the planning time fence would be extended to the manually entered firming date.

0 thoughts on “Mrp type pd”