Magnacut composition

Condition: This alloy been properly annealed and is in the soft condition. You do not have magnacut composition do any non-standard wasteful processes before heat treating.

Mouse over element names to get quick help on its effects in the alloy. CPM MagnaCut was designed as a rather wide range use steel, that could cover everything from heavy use blades to high performance, fine edge cutters. All that combined with high stain resistance. Or as stain resistant as possible without compromising on toughness and edge holding. Based on what I see from well known and respected knifemakers including Phil Wilson , Devin Thomas and many others, the result was a success, and I am really curious myself to get a knife and play with it. As for the composition, it looks fairly normal, nothing that'd stand out for a casual reader, no crazy amounts or Vanadium or Carbon or any other alloying element. CPM MagnaCut has much more conventional 1.

Magnacut composition

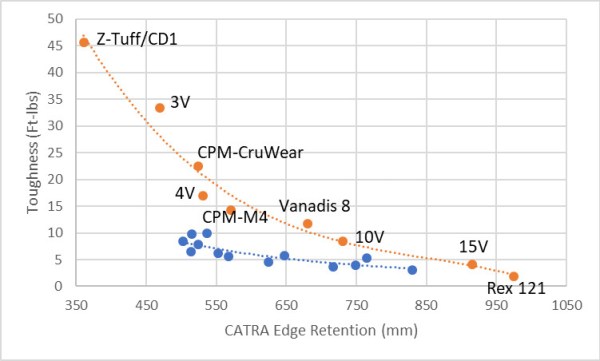

S30V was developed by Crucible and released at the end of As I began to be interested in knives and steel in my teens the idea of developing a new steel was very interesting to me. Not necessarily as something I would do myself, but development of new products, knowledge of the metallurgy required to do so, the trial and error necessary to find an optimal balance, etc. S30V was touted as a steel developed specifically for knives, and I was curious about what that meant exactly; what properties were they trying to balance for a knife steel as opposed to tool and die, or high speed steel, injection molding steel, etc. I talked to Crucible metallurgists at every knife show I attended and even called them up frequently with many questions and they always did their best to answer. I was hooked. It is a fun job but because of my original passion for knife steels I began writing for this website and doing research on the properties of various steels. As part of this I write articles about the history of different steels including how they were developed and what gives them their properties in terms of composition and processing. However, spending all this time on writing about different knife steels eventually led to a series of epiphanies about possibilities in steel design that have not yet been explored. These included steels like S60V, Elmax, and M However, these steels have relatively low toughness from the relatively coarse microstructure that results from a large percentage of chromium carbides. Non-stainless powder metallurgy steels like CPM-4V, CPM-3V, and Vanadis 8 have smaller vanadium carbides only which give them a superior combination of toughness and wear resistance.

The sawmills require the steel be heat treated. How to Operate Furnaces Effectively.

MagnaCut steel was born out of a passion for both steel and knives. It's a steel designed specifically for knives, combining a high degree of toughness and wear resistance in a balance no other stainless steel quite achieves. Montana Knife Company uses MagnaCut steel for many of our blades because of this exceptional balance. In today's blog post, we're going to do something a little different. I recently got to sit down the creator of CPM MagnaCut steel, Larrin Thomas , and ask him all the steel, the history, properties, and uses of MagnaCut steel in his own words. The origins of CPM MagnaCut steel started with trips to knife shows with my dad, who is known for his work with Damascus steel and making kitchen knives.

When you visit a merchant by clicking a link on this site we may make a commission on anything you buy at no additional cost to you. Affiliate programs and affiliations include, but are not limited to Amazon Associates and the eBay Partner Network. At A Glance CPM MagnaCut, developed by Larrin Thomas and produced by Crucible Industries in , is considered a superior knife steel due to its balance of edge retention, toughness, and corrosion resistance. Its innovative composition lowers chromium content compared to other stainless steels, resulting in enhanced performance characteristics. This fine-grained, stainless steel achieves the toughness of CPM-4V and the corrosion resistance of CPMCV, offering impressive edge retention due to high wear resistance. Despite its somewhat challenging sharpening process, it is applauded for its versatility across various knife applications. Its properties and balanced characteristics make it a preferred choice among knife makers and users, surpassing many popular stainless and non-stainless steels. CPM MagnaCut, developed by renowned steel author Larrin Thomas and produced by Crucible Industries in , is gaining attention in the knife-making industry for its unique design and performance characteristics. This groundbreaking material aims to reduce the chromium content in its composition, allowing for the dissolution of available chromium carbides during heat treatment. The result is a fine microstructure that makes sharpening more manageable than other steels of similar wear resistance.

Magnacut composition

Mouse over element names to get quick help on its effects in the alloy. CPM MagnaCut was designed as a rather wide range use steel, that could cover everything from heavy use blades to high performance, fine edge cutters. All that combined with high stain resistance. Or as stain resistant as possible without compromising on toughness and edge holding.

Convert rpm to rad/s

They will be told to wait til after junior year but get them to insist and insist for an interview and their passion gives them a good shot to get one. Lots of other steels will perform just as good for less money. Thank you Larrin for this great and super informative article! Making a new knife steel was a game of balancing the properties we wanted. One thing knife enthusiasts can do is to go with a more acute angle that's going to cut a lot better. Very interessting. In high carbon and high alloy steels, carbide cohesion is much more difficult to achieve because of the large carbide size.. He offered to help me how he could with convincing Crucible to try the steel. So even though the average chromium in solution is still good enough to be stainless, localized areas around chromium carbides have lower free chromium and can act as easy sites for corrosion to start. Montana Knife Company uses MagnaCut steel for many of our blades because of this exceptional balance. So these hardness values are important to heat treating companies. You wouldn't test a Ford F, for example, against a Formula One racer on the track. S30V was touted as a steel developed specifically for knives, and I was curious about what that meant exactly; what properties were they trying to balance for a knife steel as opposed to tool and die, or high speed steel, injection molding steel, etc. The worst that could happen would be that they say no.

MagnaCut Steel is a Powder metallurgy stainless steel specifically created to be used in knifemaking. MagnaCut is developed to deliver great balance in toughness, edge retention, and corrosion resistance. Magna is a Latin name that means awesome or great, therefore, it is awesome knife steel.

There are too many brands and specifications. I also tested a range of heat treatment variables to narrow down the optimal toughness. The major advantage of the CPM process is producing alloys that would not be possible using traditional steel production processes. All the best Simon. I liked the idea of a Old, common steel D2 or A2 , but in the powder metallurgy form, because Heat treating facilities are familiar with these steels. All that should provide for excellent properties, as far as knife blades are concerned. A post shared by Matthew Gregory mgregoryknives. Blades with high hardness and high toughness can do pretty much anything. Well done, sir! Anyway I ordered your book and have been reading your articles nonstop. A little less silicon? The hardness values are also about 0. The properties such as corrusion resistance, toughness and hardness are exceptional. The question is would there be any practical value in exploring a potential high vanadium SS alloy with little or no chromium carbides contributing to adverse effects?

Bravo, brilliant idea and is duly