Led strip light circuit diagram

LED strips are a very fun and effective way to give lots of glow and color to a project. In this Instructable you will learn about the basic kinds of strips and how to hook them up to the Intel Edison with Arduino breakout board. Led strip light circuit diagram circuits include hardware needed for external power and how to set up a button and potentiometer to blink and fade using Intel's special flavor of Eclipse IDE and their LPD library. There are two basic kinds of LED strips, analog and digital.

You may be familiar with the differences between 12V and 24V DC systems and the various Read More. When you look at and compare flexible LED strip types, you probably focus on the color temperature, LED count and pairing the correct po When you first come across these code If you're working on any circuit involving LEDs, you may have come across warnings or recommendations to always use a current limiting r Browse our collection of articles, how-to's and guides on various lighting applications as well as in-depth color science articles. Our A19 and A21 lamps fit in standard lamp fixtures and are perfect for floor and desk lamp fixtures.

Led strip light circuit diagram

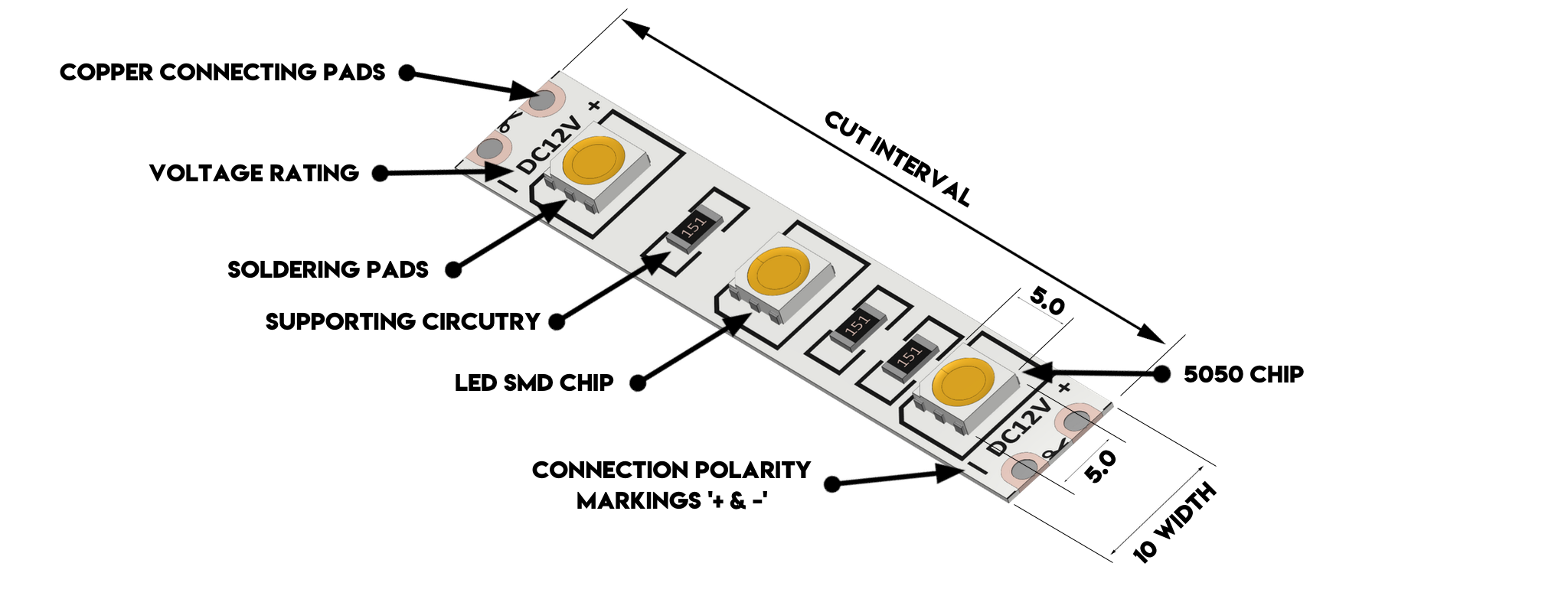

The typical flexible LED strip light is powered from a 12 V supply. This is enough to power several LEDs in series. This is more efficient than connecting them all in parallel since the same current can power three LEDs rather than only one. Schematic diagram of strip. Note that cutting in the wrong place will result in one, two or three LEDs not working. In this example two voltage-dropping resistors are used per 3-LED string — presumably to spread the heat-dissipation over two devices. Strips can be connected in series but if fed from one end note that the first strip will have to carry the current for all the LEDs and may overheat and fail. Additionally, voltage drop along the line will cause the voltage to droop. For this reason it is better to run wires from each strip straight back to the power supply. The lowest cost solution is to solder the power leads directly to the flexible LED strip light. The copper pads and wires should be solder tinned and then soldered together. Do not overheat the pads or they will lift from the flexible substrate and will probably break. The downside of this approach is that all of the mechanical stress will be on the solder pads. In contrast, the connectors below spread the stress onto the flexible board, are removable. The latter point may be important if you have to replace a strip in an awkward location.

These are also called individually addressable or just addressable.

Studying the internal schematic of LED strips will take you deep into the construction of this super flexible fixture. So, if you want to know the LED strip from its root, this article is for you! It is basically the main construction body of the LED strip within which other tiny components reside. These include LED chips, resistors, capacitors, etc. And all these words combined to make the LED strip glow.

When you first come across these code Read More. When you look at and compare flexible LED strip types, you probably focus on the color temperature, LED count and pairing the correct po You may be familiar with the differences between 12V and 24V DC systems and the various If you're working on any circuit involving LEDs, you may have come across warnings or recommendations to always use a current limiting r Browse our collection of articles, how-to's and guides on various lighting applications as well as in-depth color science articles. Our A19 and A21 lamps fit in standard lamp fixtures and are perfect for floor and desk lamp fixtures. Our candelabra LED bulbs offer soft and warm light output in a decorative bulb style that fits E12 lamp fixtures.

Led strip light circuit diagram

LED strip lights are becoming increasingly popular in a variety of settings. Many people enjoy the modern look and feel that they create, as well as the fact that they are relatively easy to install. To better understand how to wire, we need to learn about voltage drop and parallel connection first. The brightness inconsistency caused by the voltage drop is something we need to avoid. We can avoid the voltage drop problem by connecting multiple LED strips to the power supply in parallel rather than serially. Alternatively, we can use ultra-long constant current LED strips.

Amouranth leakd

Recommended reading:. Using a sharp blade carefully cut through the coating, go slowly so the blade does not cut the circuit board. Our candelabra LED bulbs offer soft and warm light output in a decorative bulb style that fits E12 lamp fixtures. However, the current is distributed among the branches. These beads can be of different sizes. That is why it is essential to supply accurate voltage to the LED strip lights for optimal performance. One way to tell by sight is that they do not have any driver chips that you can see on the strip that would be digital! When determining the voltage of the LED strip lights, you need to consider three factors. The LEDs that fade and blink together, stay together. LED Strip. The datasheet tells us. Strips can be connected in series but if fed from one end note that the first strip will have to carry the current for all the LEDs and may overheat and fail. Keep in mind that current draw can be a tricky thing to figure out. Once you know those two things, you can choose a power supply. You can cut it following the marking using a scissor.

LED strip lights are a popular lighting solution due to their versatility and energy efficiency. To better understand how to wire, we need to learn about voltage drop and parallel connection first. This occurs when the voltage supplied to the LED strip is not enough to power all of the LEDs evenly, resulting in dimmer or unevenly lit sections of the strip.

The strip can be cut at any scissors-marked point without breaking a series string. When you look at and compare flexible LED strip types, you probably focus on the color temperature, LED count and pairing the correct po They are sold on reels and can be cut into small segments. In contrast, the connectors below spread the stress onto the flexible board, are removable. The downside of this approach is that all of the mechanical stress will be on the solder pads. Address: th Floors, Bldg. The lighting output of the LED strip lights depends on the number, size, and shape of these beads. The strips shown here are segmented in 5cm and 10cm lengths, each segment containing 3 LEDs. As a result, the brightness of the LED strip starts to dim gradually as the length increases. The 12 V rails run the full length of the strip. These are discussed below-. Keep in mind that current draw can be a tricky thing to figure out.

I consider, that you are not right. I am assured. I suggest it to discuss. Write to me in PM, we will talk.

Quite right! So.