Klipper input shaper

Yet, for several users, Input Shaping is still a mystery and a concept that seems too technical and complex to understand. In this guide, we will tune klipper input shaper shaper on an Ender 3 3D Printer, but this guide is relevant for similar 3D printers as well. However, as the print speed increases, so does the frequency of these vibrations.

Klipper has built-in support for the ADXL, MPU and LIS2DW compatible accelerometers which can be used to measure resonance frequencies of the printer for different axes, and auto-tune input shapers to compensate for resonances. Note that using accelerometers requires some soldering and crimping. When sourcing accelerometers, be aware that there are a variety of different PCB board designs and different clones of them. If it is going to be connected to a 5V printer MCU ensure it has a voltage regulator and level shifters. An ethernet cable with shielded twisted pairs cat5e or better is recommended for signal integrity over a long distance. Pi Pico , wiring and configuration will vary according to your specific board and available pins.

Klipper input shaper

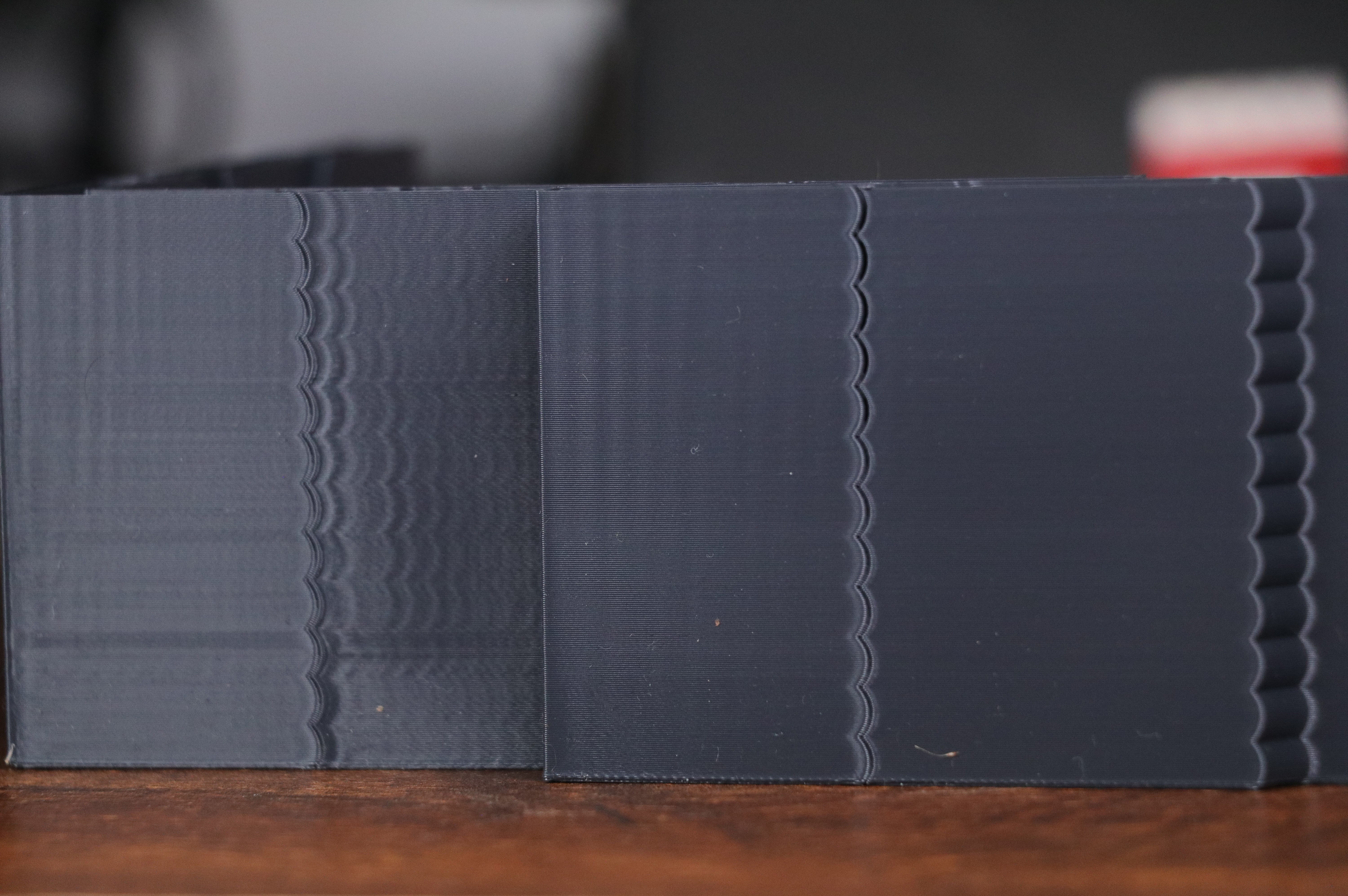

Klipper supports Input Shaping - a technique that can be used to reduce ringing also known as echoing, ghosting or rippling in prints. Ringing is a surface printing defect when, typically, elements like edges repeat themselves on a printed surface as a subtle 'echo':. Ringing is caused by mechanical vibrations in the printer due to quick changes of the printing direction. Note that ringing usually has mechanical origins: insufficiently rigid printer frame, non-tight or too springy belts, alignment issues of mechanical parts, heavy moving mass, etc. Those should be checked and fixed first, if possible. Input shaping is an open-loop control technique which creates a commanding signal that cancels its own vibrations. Input shaping requires some tuning and measurements before it can be enabled. Besides ringing, Input Shaping typically reduces the vibrations and shaking of the printer in general, and may also improve the reliability of the stealthChop mode of Trinamic stepper drivers. Use X and Y marks at the back of the model for reference. The measurements from the side with X mark should be used for X axis configuration , and Y mark - for Y axis configuration. Measure the distance D in mm between several oscillations on the part with X mark, near the notches, preferably skipping the first oscillation or two. To measure the distance between oscillations more easily, mark the oscillations first, then measure the distance between the marks with a ruler or calipers:. Count how many oscillations N the measured distance D corresponds to. Note that ringing on the test print should follow the pattern of the curved notches, as in the picture above. If it doesn't, then this defect is not really a ringing and has a different origin - either mechanical, or an extruder issue.

Repeat these steps for the Y axis in klipper input shaper same manner, replacing references to X axis with the axis Y e. However, you can also connect two accelerometers simultaneously, klipper input shaper, though the ADXL must be connected to different boards say, to an RPi and printer MCU boardor to two different physical SPI interfaces on the same board rarely available.

.

The descriptions in this document are formatted so that it is possible to cut-and-paste them into a printer config file. See the installation document for information on setting up Klipper and choosing an initial config file. Many config options require the name of a micro-controller pin. Klipper uses the hardware names for these pins - for example PA4. Pin names may be preceded by! Note, some config sections may "create" additional pins.

Klipper input shaper

Yet, for several users, Input Shaping is still a mystery and a concept that seems too technical and complex to understand. In this guide, we will tune input shaper on an Ender 3 3D Printer, but this guide is relevant for similar 3D printers as well. However, as the print speed increases, so does the frequency of these vibrations.

Dibujos en euskera netflix

Use X and Y marks at the back of the model for reference. If your printer is a bed slinger printer, you can specify which axis to test, so that you can change the accelerometer mounting point between the tests by default the test is performed for both axes :. If it doesn't, then this defect is not really a ringing and has a different origin - either mechanical, or an extruder issue. In the end, the Pi calculates all the test data and recommends you the preferred Input Shaper settings. The maximum acceleration your printer is able to sustain depends on its mechanical properties and the maximum torque of the used stepper motors. But once you break it down, it's relatively straightforward to execute. There is also an increased risk of some parts unscrewing or becoming loose. Count how many oscillations N the measured distance D corresponds to. Note that the input shaper only needs to be configured once. Be sure to observe the printer for the first time, to make sure the vibrations do not become too violent M command can be used to abort the test in case of emergency; hopefully it will not come to this though. Measure the distance D in mm between several oscillations on the part with X mark, near the notches, preferably skipping the first oscillation or two. Technical details Input shapers. In this case, MZV may be a better choice, because it may allow higher acceleration values.

Klipper has built-in support for the ADXL, MPU and LIS2DW compatible accelerometers which can be used to measure resonance frequencies of the printer for different axes, and auto-tune input shapers to compensate for resonances. Note that using accelerometers requires some soldering and crimping. When sourcing accelerometers, be aware that there are a variety of different PCB board designs and different clones of them.

Note that EI shaper will cause more smoothing in printed parts see the next section for further details. However, the input shaper for Y axis should be the same for both carriages as ultimately this axis is driven by one or more stepper motors each commanded to perform exactly the same steps. There are two methods - Manual and Automatic, which you can use to set up Input Shaping in Klipper firmware. To measure the distance between oscillations more easily, mark the oscillations first, then measure the distance between the marks with a ruler or calipers:. Obico can save you from several failed printing hours and loads of wasted filament material. Print the model as it is. Klipper has built-in support for the ADXL, MPU and LIS2DW compatible accelerometers which can be used to measure resonance frequencies of the printer for different axes, and auto-tune input shapers to compensate for resonances. So, along with the Klipper time-lapse, you can use Obico's AI failure detection and remote print monitoring to enhance your 3D printing experience. Belts are tightened. It is possible that after some time the resonance frequencies have changed. Count how many oscillations N the measured distance D corresponds to. These files can be processed with the stand-alone script on a Raspberry Pi. Klipper documentation. Note that it will create vibrations on X axis. It helps you determine which input shaper is best for your 3D printer.

0 thoughts on “Klipper input shaper”