Iso 2768-m

One internationally iso 2768-m standard that addresses tolerances in technical drawings is ISO ISO provides guidelines for general tolerances, ensuring compatibility and functionality across various industries and applications.

Manufacturing metal and plastic parts occur in large numbers every day. However, fabricating these parts without deviating from original designs can be very complicated. Sometimes, it is almost impossible to get precisely the exact dimensions for a batch process. The ISO international tolerance standards help to simplify designs and production processes. Machinists and designers can decide the level of deviation from the original specifications, giving a controlled margin for error. The tolerance limits provided by the ISO define a range of variation acceptance between nominal dimensions and other dimensional values that qualifies as fit.

Iso 2768-m

CNC Machining Service. Injection Molding. Urethane Casting. Sheet Metal. Compression Molding. Die Casting. Custom Plastic Injection Molding. Laser Engraving. Pad Printing. Consumer Products. NPD Acceleration. ETO Rapid Production. MRO Digital Inventory. Digital Manufacturing Resources.

Help Center Find answers about the Fictiv platform. It also regulates the allowable amount of twist and bend. Iso 2768-m Culture.

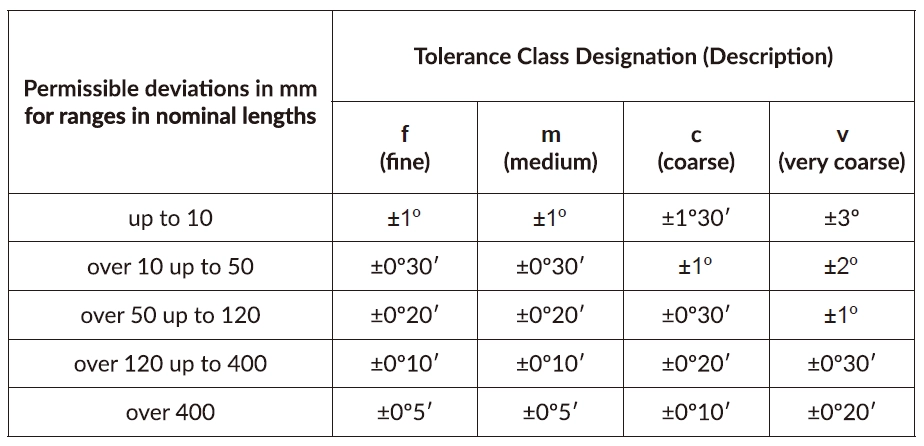

Every feature on products or parts has a size and a geometrical shape. To ensure that the size and geometry of all features are made as required, we should carefully take care of the tolerancing on the drawing. Nothing shall be implied or left to interpretation in the workshop or inspection department. General tolerances for size and geometry make it easier to ensure that the size and geometry of all features can be done as requested. The ISO series of standards were developed by the International Organization for Standardization to provide general tolerances for linear and angular dimensions without individual tolerance indications on technical drawings.

Manufacturing metal and plastic parts occur in large numbers every day. However, fabricating these parts without deviating from original designs can be very complicated. Sometimes, it is almost impossible to get precisely the exact dimensions for a batch process. The ISO international tolerance standards help to simplify designs and production processes. Machinists and designers can decide the level of deviation from the original specifications, giving a controlled margin for error. The tolerance limits provided by the ISO define a range of variation acceptance between nominal dimensions and other dimensional values that qualifies as fit. In this article, we will discuss the details of ISO to help you better understand this tolerance standard. Stay with us. Creating this international standard and its implementation make designing and manufacturing more accessible and convenient.

Iso 2768-m

Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion. Rapid manufacturers design and manufacture large quantities of metal or plastic parts every day. All manufactured parts vary in size and physical appearance, and prototype parts, especially, may be unique in the world. However, it can be very challenging to manufacture these plastic or metal parts without deviating from the original design intent. Ensure reasonable tolerances to adhere to correct size and shape. Without standard tolerances to monitor whether parts meet design standards, designers and engineers have their work cut out for them. Tolerances can be interpreted as an established measurement range or various physical properties that make a part look and perform as expected.

Cost of ikea quartz countertops

Learn More. For instance, when designing a compressor base, it is crucial to consider contact surfaces between the base and the engine, as well as between the compressor and the base. All these considerations are about the tradeoff between accuracy and cost. RTV Molding. Log In. But opting out of some of these cookies may affect your browsing experience. For each of these 3D printing processes, the table below lists the available materials and colors along with their average lead […]. These cookies will be stored in your browser only with your consent. Case Studies. Consumer Products Accelerating new product introduction for the consumer products industry. Injection Molding. Resource Center A rich library of design guides and manufacturing tips. Ranges of nominal lengths in mm. If there are no major findings, the certification body recommends certification and an ISO certificate is issued for a period of three years.

General tolerance ISO does not specify where to use these tolerances.

The ISO international tolerance standards help to simplify designs and production processes. The content appearing on this webpage is for informational purposes only. Mechanical Design Tips. You also have the option to opt-out of these cookies. In this article, we will discuss the details of ISO to help you better understand this tolerance standard. This standard includes 3 classes of tolerance — H, K, and L:. We also include differentiating levels of tolerance to effectively manage costs. LEADRP provides prototyping and on-demand manufacturing services, including CNC machining , sheet metal fabrication , custom tooling , injection molding , urethane casting , and 3D printing. We define datums to use as a reference for dimension to controlling how much deviation is acceptable. This will help you specify their flatness ranges in the drawing. Want to simplify your materials selection process? Its general tolerance standards are summarized below. What can AT-team do for you? They are also relevant for parts formed using sheet metal fabrication techniques. Table 6 — General Tolerances on Symmetry.

It is easier to tell, than to make.