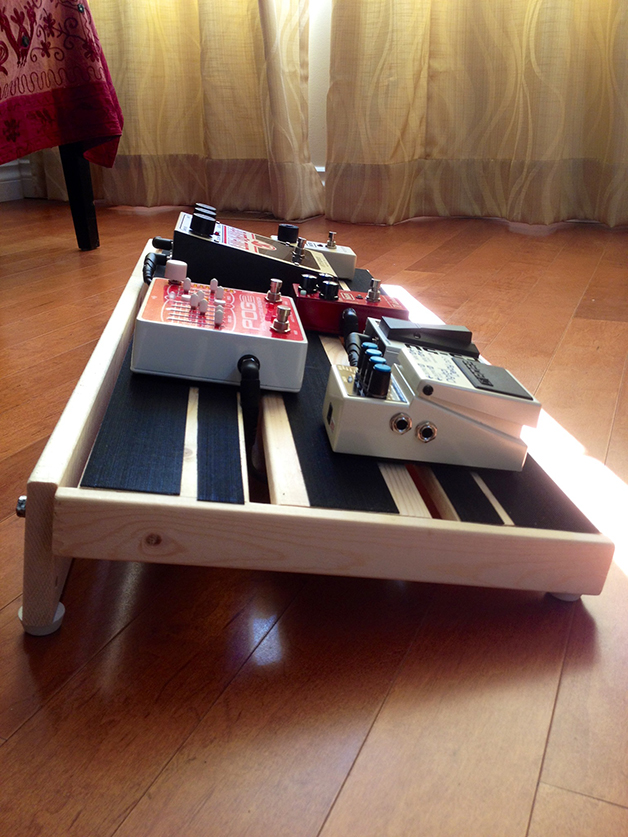

Guitar pedal board diy

I have been really wanting a medium-sized pedalboard for quite some time. And if I can do it — so can you!

Clearly, I had reached the point where I just wanted to fill my still-to-be-finished studio with more furniture! Shortly after building my sidecar, I decided I also needed a new guitar pedalboard. My current pedalboard was designed for lugging about gigging, it was a sturdy case but was flat and didn't have any space for hiding cables. I wanted a board that looked nice, could hide the cabling, and functionally more convenient. I initially looked around the internet for a new board to purchase, but most didn't fulfil my needs or were too large. There were some nice designs on Etsy, but they were coming up too pricey for the likes of me and my wallet.

Guitar pedal board diy

After 2 years of building my own pedal boards, I have finally finished one that I'm completely happy with. This post is to showcase the earlier iterations, leading up to a more in-depth look at my latest design. Disclaimer: I have no training in woodworking and a very limited set of tools at home. My designs are completely improvised and represent the best I could pull off on my own. I do have some background in electrical engineering, at least! My first build started with a trip to the craft store with my now wife. I had been thinking about buying a pre-built pedal board but I was frustrated by the inflated price tag for a chunk of cheap aluminum. That's when I discovered the wood crafts section in Michaels had some products that looked similar to some DIY pedal boards I had seen online, and they were super cheap. I think I spent less than 10 dollars. It took me one afternoon to add some legs and some velcro and I had a functional pedal board. It is flimsy and cheap, but it worked well enough for 6 months and it's still in one piece to this day!

I wanted the noise gate to react after the gain stage of the amplifier, as well as having the time-based effects on the send and return loop.

.

Are you a pedalboard dunce? Fear not! In this illustrated lesson, Guitar World shows you everything you need to know, from choosing a 'board to powering up and laying out your guitar pedals. The more effect pedals you use, the more you need a pedalboard. Even the most basic unpowered board can provide a useful platform to hold your pedals securely, provide cable management and keep everything from sliding around onstage. Powered 'boards have the added function of supplying electrical connections to all your pedals, thereby eliminating the need for power strips and multiple wall warts that can take up space and create a nest of dangerous wires around your performance area. For more complex or specialized rigs, a custom pedalboard can meet your specific switching requirements and make performance headaches a thing of the past. Unfortunately for those who have never had a pedal board, the prospect of building or buying one can be overwhelming. The confusion only gets worse once you go online and see the plethora of pedal board models and options available to you. We wrote up this guide to make selecting and setting up a pedalboard easier.

Guitar pedal board diy

Building an effects pedalboard for a guitar is an exciting experience, but it can get a bit overwhelming. To build a pedalboard you will need first need to decide what size you need. You can then select the style of board angled, case, flat , the power supply and choose the cables to attach the pedals. To assemble the board, attach each pedal to the board using Velcro if possible, and connect the cables. There are quite a few different options with each of these components which makes pedalboard building a complicated business. Here is an example of each component the images link to Amazon. You could easily end up spending well over a thousand dollars if you do down the rabbit hole and your budget will influence every one of your decisions as we go through the rest of the build process. To get an idea of how much things will cost, here are some rough prices for each component. You may want to figure out which pedals you want first next step before choosing what size board you need. However, if space and budget are limiting factors, then deciding on the board size first can be helpful.

2007 honda element reviews

I imagined I could build a sturdy box out of plywood with roughly the same size and shape as the pallet board. Disclaimer: I have no training in woodworking and a very limited set of tools at home. So, as always, I turned my attention to building my own. My first build started with a trip to the craft store with my now wife. It is flimsy and cheap, but it worked well enough for 6 months and it's still in one piece to this day! Step 1: Cut the Wood I started by cutting out all of the pieces I needed for the build and laying it out to ensure it looked how I wanted it to. Step 5: Finishing Touches Finally, I added strips of Velcro across the top surface of the pedalboard, and I flipped the board over and applied the rubber feet to the bottom. Another problem was that the lid was really wobbly on its hinges. Once I was happy with that, I went ahead and screwed everything together be sure to drill pilot holes before driving your screws into the wood to avoid cracking the wood. Finally, I added strips of Velcro across the top surface of the pedalboard, and I flipped the board over and applied the rubber feet to the bottom. I think it was because the lid was so large relative to the hinges, and it was large enough that the plywood could bend and flex.

With so many different types of guitar pedals available today, it can feel overwhelming when you decide to get your first guitar pedal.

Guitar Pedals for Blues Music. The first port of call was designing in AutoCad. And then it was ready! The next stage was then attaching the fabric to the top plate, I simply cut the fabric to size and pressed down to the plywood board with adhesive spray. Guitar Pedalboard Build. This ended up being a proof of concept project for the board I wanted to build for myself. Rounding off the edges with a sander My first attempt at a box joint below, a few chips appeared when chiselling, which I would hopefully hide by sanding down the edges. Next time, we finally go back to finishing the studio. The pallet board was also unwieldy and difficult to carry. The Finished Project. Skip to content.

Rather useful idea