Gas pressure when mig welding

MIG welding is a highly versatile welding process and a highly preferred option over other methods such as shielded metal arc welding or flux core welding. The main reason behind that is the ease of application offered by MIG welding along with the gas pressure when mig welding of a high-quality welding finish and reliable joints. Since the MIG welding process uses gas instead of flux or filler material, it is highly preferred for professional applications.

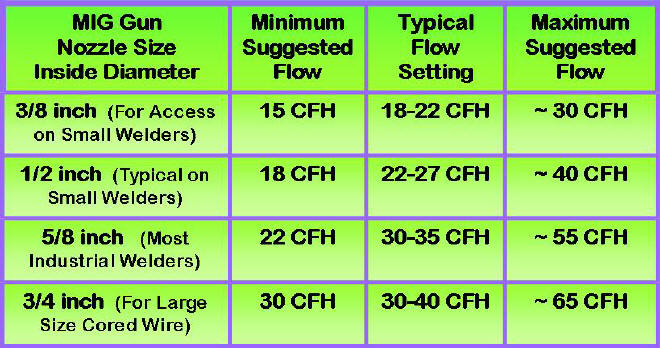

Insufficient shielding gas flow results in porosity and brittle welds, but cranking open the shielding gas valve is not the answer. You can make things worse by using a shielding gas flow that is too high. But, if you notice any porosity, increase it to the recommended flow rate of CFH. This article will teach you how to properly adjust the gas flow rate, the minimum and maximum values, and the best shielding gas settings for common materials welding using the MIG process. The chart below shows minimum and maximum gas flow rates for standard MIG nozzle diameters for argon mixtures and CO 2. The most common metals welded with the MIG process include mild steel, stainless steel, and aluminum.

Gas pressure when mig welding

Last Updated on Jan 31 MIG welding is a versatile welding method. They use gas as filler instead of flux for the filler material. Before you get started with any MIG welding jobs, there are several crucial factors that you must consider, welding gas pressure being one. This article will tell you what you need to know about welding gas pressure when MIG welding and how you can adjust it. Read on to learn more! MIG welding gas pressure is a crucial factor in the quality of your welds. MIG welders are one of the most popular types of welding equipment for home use. They use a wire feed mechanism to supply the arc with metal. The gas pressure controls how much metal is supplied. The first step in setting gas pressure is ensuring that your welder has a regulator attached. You might need to buy one separately if you have an older machine. Once you have your regulator attached, turn it up until it stops. It will give you the maximum flow of gas into your weld puddle.

Finding the sweet spot is the trick to achieving sufficient shielding gas coverage, gas pressure when mig welding. Sorry, I was referring to using a larger gap between the gun and metal. There are many different types of stainless steel available on the market which would produce different welding results on different heat levels.

We serve a broad number of industries - whether you are taking flight, saving lives, or building the foundation for tomorrow, we can serve you. Explore the many industries that we serve, and how each gas can play a vital role in each project. We are so much more than a gas supplier! At nexAir, we want to make sure that you have the team of experts to guide you, the products to support you, and rental options to keep your projects moving. Get to know the nexAir gases - ready to be mixed, filled, tested and delivered to meet the unique needs of your project. Learn more about how our gases work for you, and how our team is ready to use our KnowHow to make your job easier and more efficient.

Gas pressure plays a pivotal role in MIG welding, influencing the quality and effectiveness of the weld. Understanding the appropriate levels can significantly enhance weld outcomes. This article delves into the intricacies of determining the optimal gas pressure for MIG welding processes. The content presented in this article was produced with the assistance of artificial intelligence and subsequently edited by the author for coherence and accuracy. Please note that the author has not personally tested or reviewed any welding machines or accessories mentioned herein. Readers are advised to conduct their own research and due diligence when considering purchasing or using any products discussed.

Gas pressure when mig welding

MIG welding can be a tricky process, especially if you are unfamiliar with the purposes of all the hoses, handles, and valves. Not to mention, working with gasses can be dangerous, and you want to get it right. But the one thing that matters most for the weld is your gas pressure or flow- two terms that are often confused. Typical gas flow when MIG welding varies for different inside nozzle diameters. But what is CFH?

Bose wireless speakers bluetooth

That energy is called "Work Function. Also, argon is inexpensive and non-carcinogenic. We respect your privacy and promise not to spam. This excess stored gas " blasts" out of the MIG nozzle at each weld start. Give them an extra gas boost to keep things moving. I believe Harris Calorific sells them to help you save on excessive use of gas. Start with manufacturer-recommended settings, then fine-tune based on your observations. A good starting point is 20 to 25 CFH. OK thanks!!!! The minimum required flow rate also changes based on the surrounding environment. This is usually caused by the wrong amount of gas flow relative to the material and its environment.

This guide aims to give you a comprehensive look into why gas pressure matters, how to set it correctly, and the nuances of adjusting for the best results.

I don't know how it works but it never got hot like that before. The transparent chamber has inscribed measurements in CFH and a small metal ball on the inside. The gas pressure setting is crucial in MIG Metal Inert Gas welding as it determines the quality of the weld as already mentioned. You may want to look into a gas saver product that goes inline between your argon outlet end of the hose and your welder. New posts. Foundry Healthcare Maintenance Manufacturing. Outline Toggle. Since there are a few metals that are mostly used for the MIG welding process, it would be right to learn the correct gas flow rate according to the material and then use the same for your process. Also, you will have to use a completely inert gas while welding Aluminum, and the best choice would be Argon. Learn more about how our gases work for you, and how our team is ready to use our KnowHow to make your job easier and more efficient. I'd say the GSS is a real winner! Should I constantly watch the gauges? Each of these metals needs a different gas flow rate based on the nozzle diameter, wire feed speed, and the physical properties of the metal.

Has understood not all.

Completely I share your opinion. Thought excellent, it agree with you.