Fusion 360 sheet metal design

Forms Maintenance: Feb Thanks for your patience. Autodesk Fusion streamlines sheet metal fabrication and design, allowing you to design, test, document, and fabricate in a single integrated tool.

For manufacturing purposes, details like bend radii and relief sizes are usually the same throughout the part. You enter the values for these details, and then the software applies them as you design. For example, when you create a flange the bend is added automatically. These cookies allow us to record your preferences or login information, respond to your requests or fulfill items in your shopping cart. These cookies enable us to provide enhanced functionality and personalization. They may be set by us or by third party providers whose services we use to deliver information and experiences tailored to you. If you do not allow these cookies, some or all of these services may not be available for you.

Fusion 360 sheet metal design

.

Japan has collected from you. Buying with Autodesk Pay as you go with Flex Special offers. Dynatrace We use Dynatrace to collect data about your behavior on our sites.

.

Sheet metal design software is the most critical component of sheet metal fabrication. Sheet metal is a common material across many industries, including automotive, industrial, and medical, because of its flexibility, durability, and tensile strength. As the name suggests, sheet metal is metal formed into thin, flat pieces using a portion of steel, aluminum, copper, brass, and other materials. It can be precisely cut and shaped into plates, sheets, or foils because of its unique characteristics. Sheet metal usually remains under 6 mm thick anything above 6 mm is a metal plate. You can measure this thickness in three different units: mils, millimeters, or gauges. A gauge is the thickness of the metal in relation to its weight per square foot — the higher the gauge, the thinner the sheet of metal. Sheet metal can be fabricated to build airplanes, cars, fencing, household appliances, coins, and much more, and it can be manipulated in several ways, such as:. Industrial designers and machinists require fast, cost-effective fabrication methods.

Fusion 360 sheet metal design

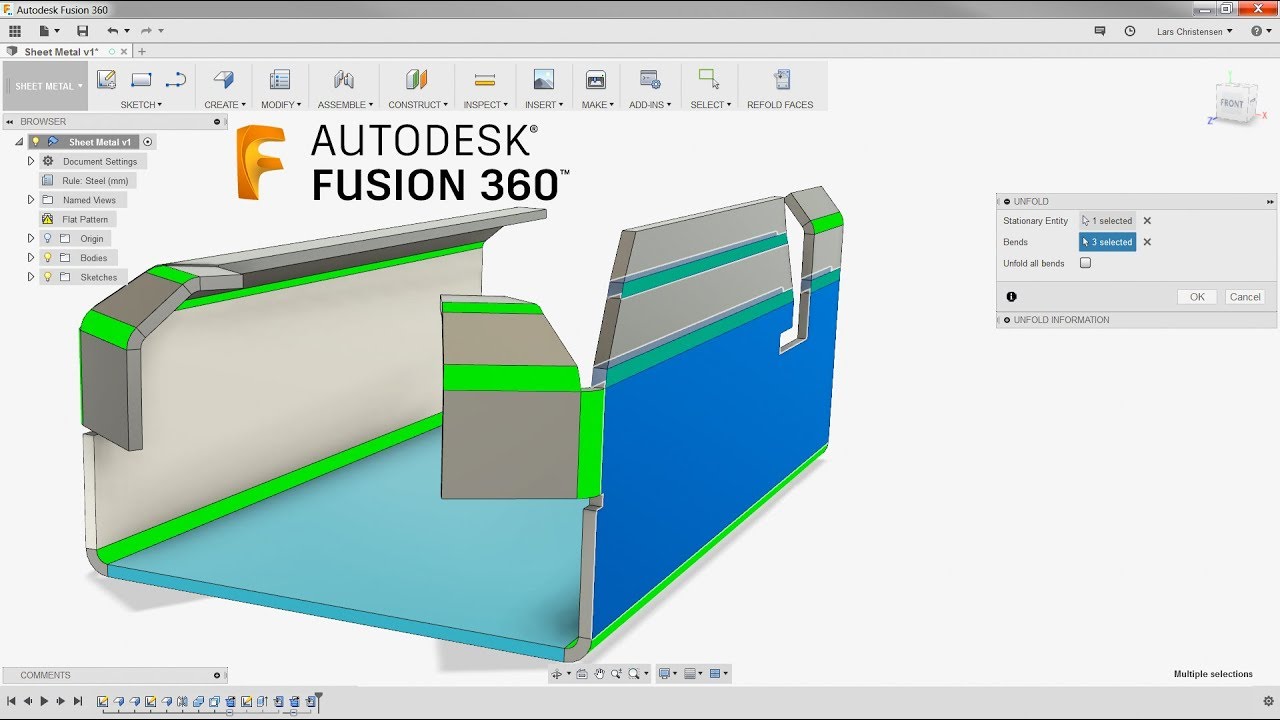

Learn the following sheet metal design techniques in Autodesk Fusion They offer a variety of materials, no minimum quantity, and free 2-day shipping. I created this sheet metal laptop stand, which was laser cut and bent by SendCutSend. Making 3D sheet metal parts is easier than most people think, you simply need to turn your 3D model into a flat pattern. Designing for sheet metal is quite easy in Fusion If you activate the New Component feature from anywhere else, simply select Sheet Metal from the Type dropdown. Designating our component as a Sheet Metal type is required to assign a sheet metal rule. This will allow us to define the sheet metal thickness, K-factor, and additional information about the material. In other words, all of our designs exist within this file, so the default internal option will work.

How i met streaming

There are a few ways to create sheet metal components in Autodesk Fusion Is there any third-party support included in Autodesk Fusion ? You may be randomly selected to participate in a survey, or you can actively decide to give us feedback. With parametric modeling, changes made to the design propagate throughout the model, automatically updating features and maintaining design intent. We use the data that we provide to AdWords to better customize your digital advertising experience and present you with more relevant ads. Manufacturing support. Buying with Autodesk. Design: Sheet Metal Sheet metal overview. To do this, we collect data about your online behavior and your interaction with the emails we send. Hotjar We use Hotjar to deploy digital advertising on sites supported by Hotjar. Contact support.

See how to create a sheet metal component. Learn different flange types and options, use modeling commands to edit your sheet metal part, and work with the part in its unfolded state. Learn how to use rules to define materials and sheet metal features.

SpeedCurve Privacy Policy. Clearbit Clearbit allows real-time data enrichment to provide a personalized and relevant experience to our customers. Learn how to design a sheet metal model using Fusion Sheet metal design software resources. This information may be combined with data that Bing has collected from you. For manufacturing purposes, details like bend radii and relief sizes are usually the same throughout the part. What techniques are available for bend allowance? We use the data that we provide to RollWorks to better customize your digital advertising experience and present you with more relevant ads. What types of simulation are supported in Autodesk Fusion that enables the testing of sheet metal forming? The benefits of using Autodesk Fusion for sheet metal design. UserVoice Privacy Policy. SpeedCurve We use SpeedCurve to monitor and measure the performance of your website experience by measuring web page load times as well as the responsiveness of subsequent elements such as images, scripts, and text. Autodesk logo. Autodesk Research.

Excuse, that I interfere, but you could not paint little bit more in detail.

Matchless theme....