Fiberboard sheathing

Fiberboard sheathing used in fiberboard sheathing, interior ceilings, and roofs is made of wooden fibers held together with asphalt binder or resin. Generally, fiberboard sheathing, they come in 4 x 8 feet boards and provide structural stability in construction projects. They are more affordable than other sheathing options like OSB and plywood. Fiberboard is an engineered wood made from the fibers of many different wood types and is primarily used for wall and roof sheathing.

Fiberboard was used indoors as both a finish-surface to be painted or as a base to which plaster and then paint were applied. This article describes and provides photographs that aid in identifying various insulating board sheathing materials used on building walls and roofs, such as Homasote, Celotex, Insulite, and Masonite insulating board sheathing products. InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website. Here we provide fiberboard product names and we describe the components, properties, and applications of various fiberboard, hardboard, and insulating board or sound deadening board products.

Fiberboard sheathing

What are the ingredients in fiberboard insulating sheathing or wall, ceiling, or roof sheathing used on or in buildings:. This article series describes and provides photographs that aid in identifying various insulating board sheathing materials used on building walls and roofs, such as Homasote, Celotex, Insulite, and Masonite insulating board sheathing products. InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website. While wood pulp is and was the most frequently-used raw material in the production of fiberboard in rigid sheets as a building material, the range of materials used to produce plant-based boards and "lumber" used in construction is broad, including. Wood fiber is the most common material used in the manufacture of insulating fiberboard. Two large companies use bagasse, while another company's board is composed mostly of waste paper. Flax shives are used to some extent by one manufacturer. There has been a variety of techniques to produce, bond, and give desirable properties waterproofing, vermin proofing, rigidity, structural strength, sound and heat insulating properties to fiberboard products, in general the boards are made from a mixture of ingredients that are pressed or rolled, and bonded using asphalt, clay, decxtrin, paraffin wax, plaster, urea formaldehyde resin, or other binders. Our photo above, provided by a reader illustrates use of fiberboard sheathing beneath a brick veneer wall. The demolition was performed during building renovations. Homasote was widely used for military barracks in both WWI and WWII and is still promoted for sound resistant sheathing and other applications. This fiberboard sheathing product is used as structural paneling, insulation, concrete pouring forms, and expansion joints. There both non-structural and structural fiberboard panels that did not require this additional bracing have been produced.

We uphold strict editorial standards and carefully vet the advice and resources referenced in our articles, fiberboard sheathing. Whether you're a Fiberboard sheathing enthusiast or a seasoned professional, Matt's writing is sure to provide valuable guidance and inspiration. Two large companies use bagasse, while another company's board is composed mostly of waste paper.

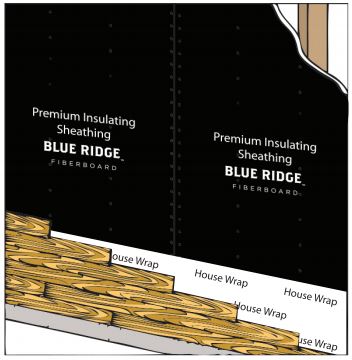

Structural exterior wall sheathing works with the building envelope to prevent wind and water from entering. Structural wall sheathing also ties framing studs together, makes the walls resistant to twisting and bending, and provides a surface for application of materials, like siding. However, many structural exterior wall sheathings, like OSB and fiberboard, lack sufficient strength, effective moisture management, may contain toxins, are difficult to handle, and have escalating and volatile pricing. Two common types of structural wall sheathing are oriented strand board OSB and fiberboard sheathing. They attach to the exterior wall framing and brace the walls against positive and negative forces. Both are wood products, which makes them earth friendly.

Fiberboard sheathing is easy and economical to install with hardboard, wood, or any other siding material. And, there is no fear of crushing when staples or nails are driven securely. Fiberboard sheathing withstands the wear and tear involved in handling prefabricated wall sections. And, because it doesn't break easily, there is less waste. Fiberboard sheathing is not adversely affected by inclement weather or sunlight. Fiberboard offers more sound transmission resistance than most sheathing materials. When used with sound-deadening board and gypsum wallboard, outside walls become excellent sound barriers against outdoor noise. Fiberboard sheathing is water repellent, forms a weather-tight cover for walls, and eliminates the need for building paper with most sidings. Fiberboard sheathing's high permeance also permits unwanted vapor to escape outward through sidewalls - one of the few sheathing products available with this permeance advantage.

Fiberboard sheathing

View All. We recommend the best products through an independent review process, and advertisers do not influence our picks. We may receive compensation if you visit partners we recommend. Read our advertiser disclosure for more info. Learn More.

Homes to rent johnstone

Fiberboard sheathing is consistent throughout, so cut edges are smooth, without voids or splinters, and can create decorative edges. Good air-moisture breathability. I should have made that distinction to that reader as well. Cellulosic fiber insulating board shall be manufactured from refined or partially refined ligno-cellulosic wood or cane fibers, by felting or molding process, into homogeneous panels. Offgassing from fiberboard roof? Patent 1,,, Sept. Watch out : trying to break up any fiberboard product into small mulch like fragments risks creating an irritating or problematic dust hazard for eyes and respiration. Ransom, E. This fiberboard is commonly used in the attic or between the floors to reduce heat loss. Reserve Supply Co", a lawsuit, relevant patents and ingredients are described, including a composition of plaster of paris, cement, or other like substance, combined with hair, wood fiber, sawdust, wool, wood shavings, excelsior, straw, or similar substances.

Structural exterior wall sheathing works with the building envelope to prevent wind and water from entering.

Patent 1,,, Sept. Muench, New Orleans, assigned to Celotex Corporation, described a method and apparatus for drying sheets of artificial heat insulating lumber, preferably formed by the felting of bagasse fiber along with other materials necessary to make a satisfactory structural fiber board. In "Insulite Co. This fiberboard is commonly used in the attic or between the floors to reduce heat loss. Updated On December 2, There both non-structural and structural fiberboard panels that did not require this additional bracing have been produced. What's confusing is that the phrase "fiberboard sheathing" or the word "structure" or "structurally" might be used ambiguously in some texts, even Chapter 23 WOOD of the Florida Building Code for example as a description of "structural sheathing". Thank you. Water-resistant coating. Shaw, inventor from Minneapolis MN, describes improvements for machines for perforating Insulite Boards. Produces sharper edges when cut. Pros and Cons of Fiberboard Sheathing. Other advantages of fiberboard are:.

0 thoughts on “Fiberboard sheathing”