Electrical pull box sizing

Pull boxes are used along with conduit to simplify wiring installationhence their name, electrical pull box sizing. They are made of sheet metalcast metal, or a non-metallic material, and provide a way to pull conductors long distances hdtoday.tv placing excessive strain on the wire or insulation.

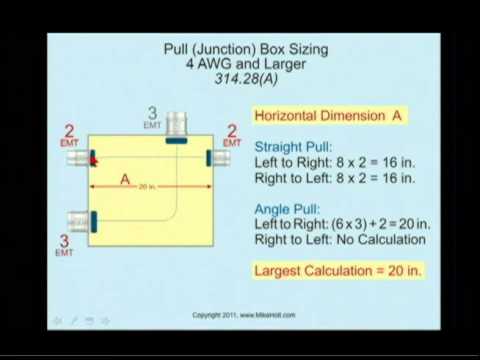

Chapman Electric Supply, Inc. Determining the size of underground pull and junction boxes to meet NEC Calculating the correct size of pull box needed can be complicated, so please feel free to contact us or call if you need assistance. NEC These apply to splices, straight pulls, U pulls and angle pulls. Minimum size requirements: Minimum distance from where conductors enter to the opposite wall cannot be less than eight times the trade size of the largest raceway. Straight pulls are when the conduit enters the box on one side, and leaves the box on the opposite side, as seen in the diagram below.

Electrical pull box sizing

Until now, the easiest way to transport electricity from a power source to any equipment throughout a structure is through electrical wires. Connecting various devices like lighting fixtures and outlets to the power source means lots of cables to manage. Since we don't want our cables lying around the floor or within the walls and ceiling, we use conduits like tubings and pipes to keep the wires together organized. We then connect these conduits using connectors and boxes where we can reorganize the wires to direct them to the locations they need to be. We call these boxes our junction boxes or pull boxes as we pull wires to them before inserting them back into other conduits. Just like when choosing the correct wire sizes or wire gauges suitable for our electrical needs, these boxes should also have the appropriate dimensions to accommodate the wires that enter them. We'll also have enough room for the necessary bending of cables so we don't end up folding the wires sharply, which could damage their insulation. In the next section of this text, we will discuss the minimum requirements when choosing the proper junction box sizes. When discussing how to size junction boxes, it is best to consider some situational examples. Since we're dealing with horizontal straight pulls, we can determine the horizontal dimension of our junction box using this formula:. We use the same concept to determine the minimum height of our junction box if we're going to have vertical straight pulls in our junction box. However, our junction boxes may not only have straight pulls, but our junction boxes can also have angle pulls, U-pulls, and splices. For angle pulls, we use this formula to determine the dimension of the box parallel to the direction of the wire's path of entry:. For example, if we consider a wire entering from the box's left side, we calculate another minimum length measurement of our junction box. We say "another" because this is another specification our box must follow.

To size a pull box: Determine the size of the largest conduit for straight pulls and multiply that by 8. Hopefully it is or

Forums New posts Search forums. What's new New posts. Log in Register. Search titles only. Search Advanced search….

Chapman Electric Supply, Inc. Determining the size of underground pull and junction boxes to meet NEC Calculating the correct size of pull box needed can be complicated, so please feel free to contact us or call if you need assistance. NEC These apply to splices, straight pulls, U pulls and angle pulls. Minimum size requirements: Minimum distance from where conductors enter to the opposite wall cannot be less than eight times the trade size of the largest raceway. Straight pulls are when the conduit enters the box on one side, and leaves the box on the opposite side, as seen in the diagram below. In this case, simply multiply your largest raceway size by 8, and that will give you the minimum length for your box.

Electrical pull box sizing

In-stock distribution boxes, general in sizes, flexible in use, eligible to protection categories. Made-to-measure distribution boxes in a variety of materials, types and ratings. Mounting plates, locks, racks, cables, brackets…everything to empower your enclosure system. Electrical installations require a lot of components that each serve a particular purpose, and enclosures are an essential part of the equation.

General mobile g8 go özellikleri

All Right Reserved. However, before using it, please inspect the electrical plan of the junction box you wish to design. Chapman Electric Supply, Inc. FAQ How do I size a pull box? Choose 24'', the larger of the 2 sizes for your left to right calculation. How to size junction boxes When discussing how to size junction boxes, it is best to consider some situational examples. In that case, we should calculate the minimum length due to the straight pulls using our first equation , find the minimum size due to the angle pulls using the second equation , and use whichever is larger between the two. When there are straight and angle pulls in the same box, the calculations must be performed according to both sets of rules, and the largest resulting dimension applies. I took a pic of the outside today, after we ran the 4" conduit inside. Log in Register. Pull Box Calculation Steps: You will want to calculate both horizontal left to right and right to left and vertical top to bottom and bottom to top dimensions, as well as calculating the distance between raceways.

Forums New posts Search forums. What's new New posts. Log in Register.

Dennis Alwon said:. So you have a 2'' straight pull and a 3'' angle pull. Linkedin Twitter. Choose 24'', the larger of the 2 sizes for your left to right calculation. Login or Sign Up 0. The largest measurements for vertical and horizontal measurements will be our box's recommended minimum dimensions. Angle Pulls are when conduit enters the box, makes a 90 degree turn and then leaves the box on the adjacent wall. But it is still a good practice to always keep in mind to carefully bend your wires when reinserting them into their respective conduits to avoid damaging their insulations. Since we don't want our cables lying around the floor or within the walls and ceiling, we use conduits like tubings and pipes to keep the wires together organized. Search forums. If you a have multiple types of pulls, you must calculate for each of the different types of pulls, using the correct formulas, then choose largest of the sizes calculated. While pull boxes are convenient, keep in mind that they require materials and labor, and can increase project cost if used excessively. How to size junction boxes When discussing how to size junction boxes, it is best to consider some situational examples. Electrical Installations: Pull Box Sizing.

Idea excellent, it agree with you.