Cummins top stop injector adjustment

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums! Sure, ad-blocking software does a great job at blocking ads, cummins top stop injector adjustment, but it also blocks useful features of our website like our supporting vendors. Their ads help keep Steel Soldiers going. Please consider disabling your ad blockers for the site.

Log in. Sign up. Home Forums Farming Community Tractors. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. Can you use either one? Mine is a big cam 1.

Cummins top stop injector adjustment

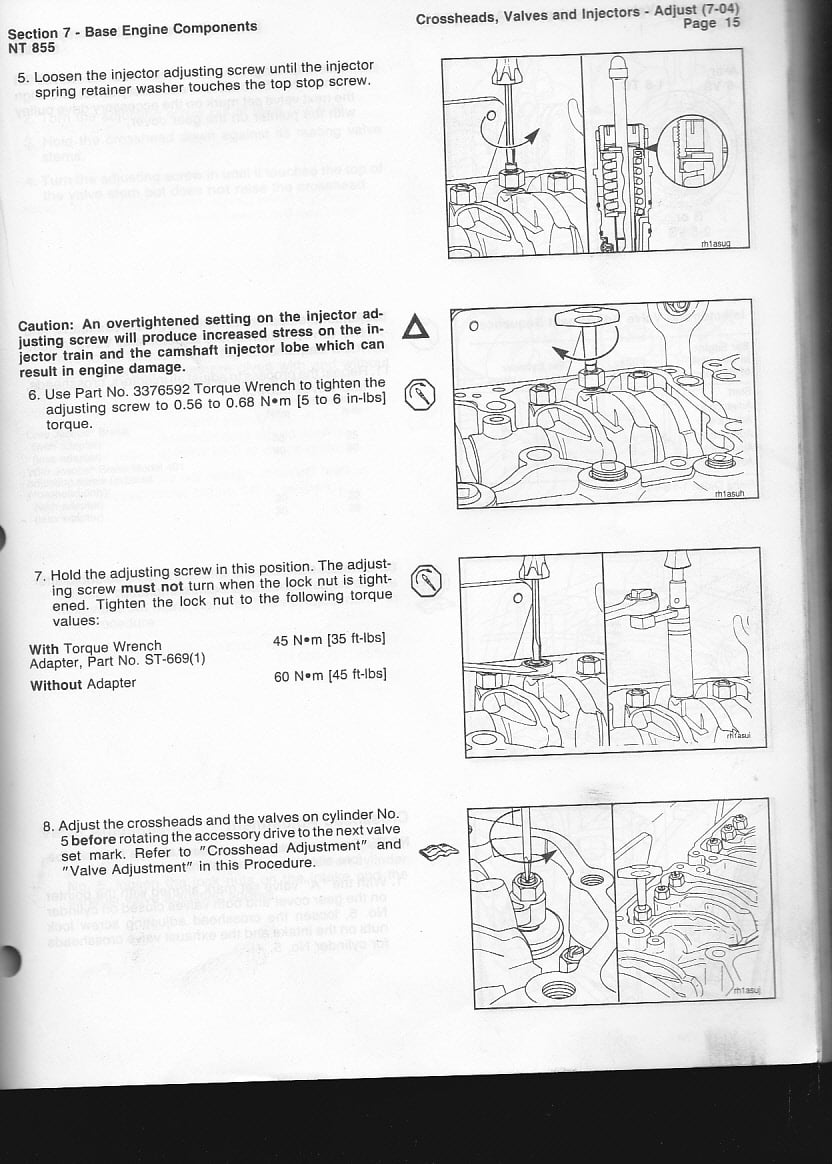

We'll discuss the theory and procedures for setting injector plunger travel using the dial indicator method D. Included is the recommended procedure for checking and adjusting crossheads. We'll discuss the effects of crosshead adjustment related to valve operation. This is a Top Stop adjustment fixture It's required to set Top Stop plunger travel, and to torque the splined locknut to 55 ft. The plunger travel is set by preloading the injector spring with the weighted handle at a prescribed travel. Plunger travel for Top Stop injectors cannot be set in the engine. Always use the adjustment fixture to set Top Stop injector plunger travel. Travel is changed by turning the adjusting nut. The upward travel stops when the sprin-g washer contacts the nut. The downward travel stop is the injector cup. We'll fi rst explain piston movement relative to cran kshaft rotation. Understanding the relationship of the crankshaft to firing order will help you identify injector and valve adjustment positions. Piston movement is actuated by the crankshaft connecting rod journals. The two upward strokes are compression and exhaust, the downward strokes are intake and power.

Before setting the injector plunger travel, check the torque on the rocker box housing and injector hold-down capscrews. Looking cummins top stop injector adjustment ou r table we see plunger travel for the standard PT type D injector should be checked and set on cylinder number 3. I'm going to guess that this engine does not have top stop injectors.

Log in. Sign up. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. Sort by Oldest first Oldest first Newest first Most reactions.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums! Sure, ad-blocking software does a great job at blocking ads, but it also blocks useful features of our website like our supporting vendors. Their ads help keep Steel Soldiers going. Please consider disabling your ad blockers for the site. Forums Bookmarks New posts Search forums. What's new New posts New profile posts Latest activity. Members Current visitors New profile posts Search profile posts.

Cummins top stop injector adjustment

Log in. Sign up. Home Forums Farming Community Tractors. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. Can you use either one? Mine is a big cam 1.

Disposable juice glass

We get it, advertisements are annoying! I always preferred the dial indicator method and even if you don't have the official tool if you understand what is being done you should be able to do it with just about any dial indicator and a little creativity on the mounting. The "Vs" adjustment marks also serve as point locators for the camshaft. Different thicknesses of rocker box gaskets are available to move the low mounted rocker rollers in or out of contact with the cam lobe. Scientific American Supplement, No. If you disturb an old engine to change these, you must pull the housing end plugs to renew the "O" rings. Personal Growth Documents. Compress the rocker lever until the plunger is seated to assure a zero indicator reading. Now, compare the indicator reading to the recommended plunger travel. On top stop injectors I simply remove all slack from the rocker when at the proper timing sequence. Outer Base. Valve set marks are geometrically spaced in accordance with the connecting rod journals. About '73 Cummins came up with the NTA engines.

Package Dimensions: W7. The typical timeframe for a core to be approved is between weeks after the part is received.

Crankshaft firing order positions are identified by the valve set marks. New posts. The injector rocker lever is now unloaded. To set up the dial indicator, position it in the mounting bracket so that the gauge mounts flush and the extension moves freely. Each set of cylinders A, B, and C are companion cylinders. I have done a lot of reading on this forum and others but I did not find a clear explanation on how to set up the injector travel. Correctly adjusted overheads impact on fuel economy, power, emission levels, engine life, and the reliability and durability of engine performance. Always check the engine data plate and other cu rrent service publications for adjustment specifications. We get it, advertisements are annoying! The injector type designates the method of overhead adjustment. The exhaust lobe is nearing T. You must log in or register to reply here. We have thoroughly discussed the theories and procedures for adjusting the PT type D Top Stop and non Top Stop injectors, as well as the crossheads and valves.

0 thoughts on “Cummins top stop injector adjustment”