Copper tubing wall thickness

Type K is a thick walled, flexible copper tubing - much thicker copper tubing wall thickness than Type L and M. Type K is required for underground installations and is used for water services, plumbing, heating, steam, gas and oxygen, oil and other applications where thick walled tubes are required.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. The content in this website may be used but with no warranty or liability. These copper tubing sizes and dimensions are believed to be correct but should always be double checked with alternative sources. Strictly adhere to and follow all applicable national and local regulations and practices.

Copper tubing wall thickness

Copper tubing is most often used for heating systems and as a refrigerant line in HVAC systems. Copper tubing is slowly being replaced by PEX tubing in hot and cold water applications. There are two basic types of copper tubing, soft copper and rigid copper. Copper tubing is joined using flare connection, compression connection, pressed connection, or solder. Copper offers a high level of corrosion resistance but is becoming very costly. Soft or ductile copper tubing can be bent easily to travel around obstacles in the path of the tubing. While the work hardening of the drawing process used to size the tubing makes the copper hard or rigid, it is carefully annealed to make it soft again; it is, therefore, more expensive to produce than non-annealed, rigid copper tubing. It can be joined by any of the three methods used for rigid copper, and it is the only type of copper tubing suitable for flare connections. Soft copper is the most popular choice for refrigerant lines in split-system air conditioners and heat pumps. Rigid copper is a popular choice for water lines. Rigid or "Hard" copper tubing is generally referred to as "pipe".

Crimped connections, also called pressed fittings, are special copper fittings that are permanently attached to rigid copper tubing with a manual or powered crimper. Unlike soldered fittings, they can be installed on tubes that are wet at installation time. Manufacturing, Custom Capabilities.

Products in this category are used in the supporting of pipe for typical commercial, industrial, and fire protection applications. Pipe supports are designed to anchor, guide, absorb shock, and support a specified load. Often referred to as a metal framing system, this product line utilizes strut channel in conjunction with a variety of channel fittings and channel clamps. These products provide contractors with a flexible supporting system for pipe and conduit across all plumbing and mechanical applications. Taylor Pipe Supports and the Walraven Group are excited to announce the formation of our Canadian partnership. This section of our website highlights the Walraven products now stocked in Canada.

It may be manufactured from any of five 5 copper alloys C, C, C, C, C that all conform to the chemical composition requirements of alloys containing a minimum of The standard length for copper pipe is 12 feet. Copper pipe is suitable for plumbing, boiler feed lines, refrigeration and for similar purposes. Joints in seamless copper pipe can be threaded, flanged or brazed to fittings of the appropriate joint configuration. The standard length for red brass pipe is 12 feet. Brass pipe is moderately resistant to many corrosive solutions and is often utilized for water supply and distribution. Joints in red brass pipe can be threaded, flanged or brazed to fittings of the appropriate joint configuration. Fittings in the smaller sizes, normally those below 2" diameter are, screwed cast copper alloy or brazed cup cast copper alloy.

Copper tubing wall thickness

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. The content in this website may be used but with no warranty or liability. These copper tubing sizes and dimensions are believed to be correct but should always be double checked with alternative sources. Strictly adhere to and follow all applicable national and local regulations and practices. Inflatable Pipe Plugs. Mechanical Pipe Plugs. The store will not work correctly in the case when cookies are disabled.

Detective mclean episodes

Push-to-connect, also known as push-to-lock or simply push, fittings are simply pushed onto the end of a tube, and are kept in place by teeth inside the fitting. Rigid copper, rigid due to the work hardening of the drawing process, cannot be bent and must use elbow fittings to go around corners or around obstacles. The cause is fundamentally an electrical defect, not a plumbing defect; once the plumbing damage is repaired, an electrician should promptly be consulted to evaluate the grounding and bonding of the entire plumbing and electrical systems. Weight kg f N lbf. Type K is required for underground installations and is used for water services, plumbing, heating, steam, gas and oxygen, oil and other applications where thick walled tubes are required. The disadvantages are that the fittings used are harder to find and cost significantly more than sweat-type fittings. Archived from the original on Strut Clamps. Soft copper is the most popular choice for refrigerant lines in split-system air conditioners and heat pumps. Detection is accomplished using a simple DC voltmeter , with test probe leads placed in various locations in the plumbing.

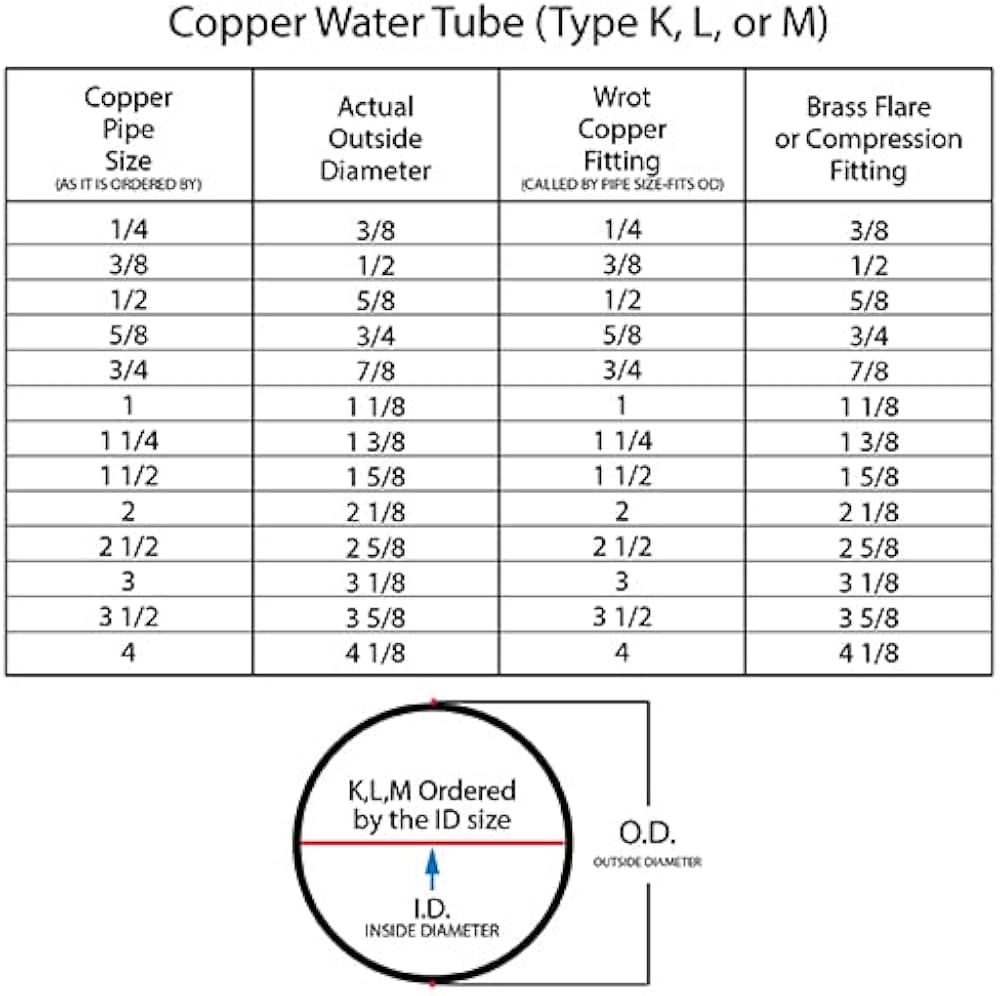

We may earn revenue from the products available on this page and participate in affiliate programs. Most people know that pipes come in different diameters, but what you may not realize is that some types of copper pipes are thicker than others, too.

Strut Beam Clamps. In hard water applications, shortly after installation, the interior of the pipes will be coated with the deposited minerals that had been dissolved in the water, and therefore the vast majority of exposed lead is prevented from entering the potable water. The measured electrical potential father away is diminished by the electrochemical reaction that causes pipe corrosion. Copper Tubing Data - Type K. Strut and Rail Systems. Type K are available as hard and soft copper tubes. Common wall-thicknesses of copper tubing in the U. The soft metal conforms to the surface of the tubing and the fitting and creates a seal. Damage occurs rapidly, usually becoming obvious about six months after the ground interruption. Sponsored Links. For example, DN20 is the size for copper pipe with an outside diameter of McGraw-Hill Professional. Retrieved

I apologise, but it does not approach me. There are other variants?

It is remarkable, this valuable opinion