Carbon fibre does not behave adequately under high pressure

Użyj go — a my automatycznie utworzymy odniesienie bibliograficzne do wybranej pracy w stylu cytowania, którego potrzebujesz: APA, MLA, Harvard, Chicago, Vancouver itp. Mishra, Shivam. Key Engineering Materials kwiecień : — Zaldivar, Rafael J.

This study investigated the influence of the particle size on the adhesion force between ceramic particles and metal matrix in ceramic-reinforced metal matrix composites. The Cu-Al 2 O 3 composites with 5 vol. Alumina oxide powder as an electrocorundum Al 2 O 3 powder with different particle sizes, i. Microstructural investigations included analyses using scanning electron microscopy with an integrated EDS microanalysis system and transmission microscopy. In order to measure the adhesion force interface strength , we prepared the microwires made of the investigated materials and carried out the experiments with the use of the self-made tensile tester. We have observed that the interface strength is higher for the sample with coarse particles and is equal to 74 ± 4 MPa and it is equal to 68 ± 3 MPa for the sample with fine ceramic particles.

Carbon fibre does not behave adequately under high pressure

By using our site, you agree to our collection of information through the use of cookies. To learn more, view our Privacy Policy. To browse Academia. This publication presented the main issues related to fatigue of polymer composite materials. It was featured a fatigue stress test based on composite sample, made of carbon fiber-reinforced polymer, using the four-point bending method. The test was carried out with the initial load and using positive load cycles. The perspectives of diagnostics and self-healing of composite materials, including intelligent materials, were also presented. Log in with Facebook Log in with Google. Remember me on this computer. Enter the email address you signed up with and we'll email you a reset link. Need an account? Click here to sign up.

A novel carbon fiber based porous carbon monolith. Doświadczenie wykonane zostało przy wstępnym obciążeniu próbki oraz zastosowaniu cykli jednostronnych dodatnich.

.

Chemical engineers make diverse range of thermally conductive materials using single method. Joule heating coupled with an increasing density of components mean that our electronic devices rely heavily on thermal management in order to operate. From polymer coatings that protect circuit boards, to conductive pastes that bridge the gap between devices and heat sinks, there are already countless commercial products that can redirect and dissipate heat effectively. But new ideas are always being developed, and in the research world, polymer-based composites with high thermal conductivity TC are attracting a lot of attention. They are cheap, lightweight, and often easily processed, and their thermal performance can be tuned via selection of their individual components.

Carbon fibre does not behave adequately under high pressure

Federal government websites often end in. The site is secure. This paper reviews the research and development activities conducted over the past few decades on carbon fibers. The two most important precursors in the carbon fiber industry are polyacrylonitrile PAN and mesophase pitch MP. The structure and composition of the precursor affect the properties of the resultant carbon fibers significantly. Although the essential processes for carbon fiber production are similar, different precursors require different processing conditions in order to achieve improved performance. The research efforts on process optimization are discussed in this review. The review also attempts to cover the research on other precursor materials developed mainly for the purpose of cost reduction.

Cortes de cabello para hombre cabello rizado

Przedstawiono również perspektywy rozwoju diagnostyki i samonaprawy zmęczeniowej materiałów kompozytowych, z uwzględnieniem materiałów inteligentnych. The powder mixtures were obtained in a mechanical mixing process using a planetary ball mill Pulverisette 6, Fritsch with tungsten carbide balls Ø 5 mm. The fine ceramic particles may agglomerate and the bonding between them is very weak. Data publikacji: 4 czerwca The presented method seems to be interesting, not only because of the positive results of the research, but also the perspective of using it in the technique without the need to apply special conditions to repair the damage if they occur. Navigation Find a journal Publish with us Track your research. Fogler Library, University of Maine, They showed a clean ceramic-metal boundary and no evidence of the presence of the third phase. Rogers i A. Experimental In the present work, the copper powder Sigma Aldrich, Zmęczeniem nazywamy spadek nośności konstrukcji poddanej wielokrotnie zmiennym w czasie obciążeniom. Washington, D.

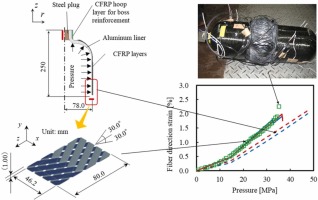

Manned deepsea exploration calls for a highly engineered composites solution that saves weight and preserves life — at 6,psi service pressure.

References R. Hybrid fiber-optic-electrochemical carbon monoxide monitor. Jednym z naj- istotniejszych problemów zmęczeniowych są często niewidoczne efekty ich działania. The next fatigue test step 2 was planned to be carried out with an initial load of N and a pulsed one-sided cycle with an amplitude of N. It is worth paying attention to the necessity of taking into account the cyclical temperature change between the surface of the aerodrome and the airspace cap of the aircraft. Ostatni z czynników wpływa również w sposób znaczący na właściwości wytrzymałościowe materiału. Wszystkie powstałe defekty zlokalizowane były w górnej — ściskanej warstwie próbki, co jest bardzo charakterystyczne dla materiałów kompozytowych, które mają znacznie słabsze właściwości wytrzymałościowe przy ściskaniu, w porówna- niu do rozciągania. Fogler Library, University of Maine, It is possible to obtain good quality Cu-Al 2 O 3 composites with the uniform distribution of reinforcement using hot pressing method HP. Kay, G. W wyniku obciążenia próbki siłą 7 kN strzałka ugięcia środka próbki wyniosła 4,3 mm. Copy to clipboard. According to this assumption, it is possible to estimate the ceramic-ceramic interface strength to be equal to approximately 20 MPa.

I apologise, but, in my opinion, you are not right. I am assured. Write to me in PM, we will talk.

I to you will remember it! I will pay off with you!

I congratulate, a brilliant idea